EN

DE ES IT FR PT NL RU FI SV NO DA PL CS SK SL HR HU RO BG EL AR TR HE LT LV ET

English (Original Instructions)

5

Apply only light pressure to the machine so that it runs

at a higher stroke rate and high material removal is

achieved.

Fine Sanding

Attach a sanding sheet with fine grain.

By lightly varying the application pressure or changing

the orbital stroke rate, the sanding plate stroke rate can

be reduced whereby the orbital action is maintained.

With moderate pressure, move the machine in a circular

pattern or alternately in lengthwise and crosswise

directions over the workpiece. Do not tilt the machine

to avoid sanding through the workpiece (e. g. when

sanding veneer).

After finishing the working procedure, switch the power

tool off.

Polishing

For the polishing of weathered paint or buffing out

scratches (e.g., acrylic glass), the machine can be

equipped with appropriate polishing accessories

such as lamb’s wool bonnet, polishing felt or sponge

(accessories).

Select a low orbital stroke rate (level 1 – 4) when

polishing in order to avoid heating up the surface

excessively.

Apply the polish onto a somewhat smaller surface than

you intend to polish. Work the polishing agent in with

a suitable polishing tool applying it crosswise or with

circular motion and moderate pressure.

Do not allow the polishing agent to dry out on the

surface, otherwise the surface can become damaged.

Do not subject the surface to be polished to direct

sunlight.

Clean the polishing accessories regularly to ensure

good polishing results. Wash out polishing accessories

with a mild detergent and warm water; do not use paint

thinner.

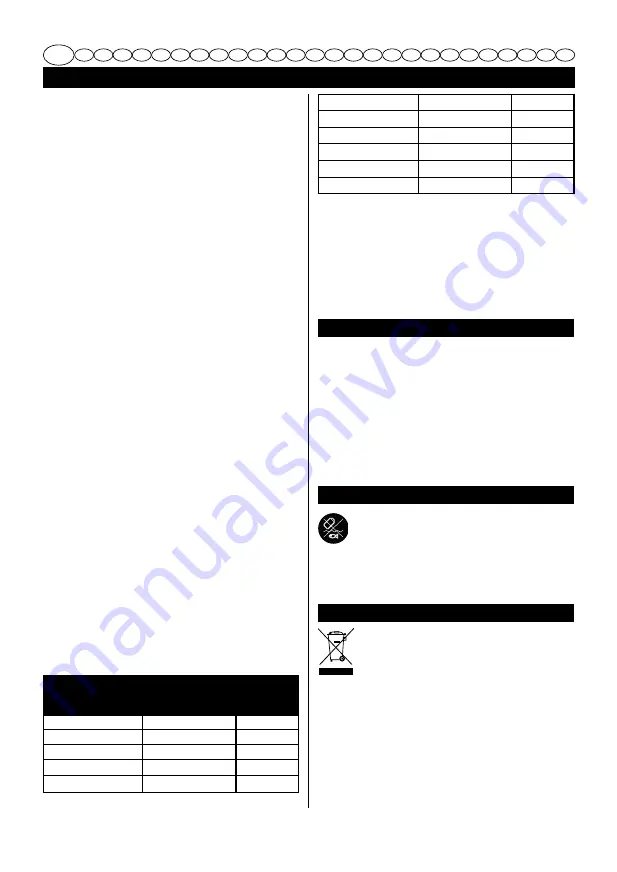

Application Table

The data in the following table are recommended

values.

The most favourable combination for working is best

determined by practical testing.

Application

Grain Size

(course sanding/

fine sanding)

Oscillation

Rate

Roughening varnish

180/240

2/3

Touching up varnish

120/240

4/5

Removing varnish

40/60

5

Softwood

40/240

5/6

Hardwood

60/240

5/6

Veneer

180/240

2–4

Aluminium

80/240

4/5

Steel

40/240

5

Derusting steel

40/120

6

Stainless steel

80/240

5

Masonry, stone

80/240

5/6

Recommendations for Optimal Handling of the

Battery

Protect the battery against moisture and water.

Occasionally clean the venting slots of the battery using

a soft, clean and dry brush.

A significantly reduced working period after charging

indicates that the battery is used and must be replaced.

Observe the notes for disposal.

MAINTENANCE AND CLEANING

■

Before any work on the machine itself (e. g.

maintenance, tool change, etc.) as well as during

transport and storage, remove the battery from

the power tool. There is danger of injury when

unintentionally actuating the On/Off switch.

■

For safe and proper working, always keep the machine

and ventilation slots clean.

When the battery is no longer operative, please refer to

an authorised after-sales service agent for power tools.

DISPOSAL

The machine, rechargeable batteries,

accessories and packaging should be sorted

for environmentalfriendly recycling.

Do not dispose of power tools and batteries/rechargeable

batteries into household waste!

ENVIROMENTAL PRORENCTION

Recycle raw materials instead of disposing

of as waste. The machine, accessories and

packaging should be sorted for environmental-

friendly recycling.