HID6506 Rotary Impact Drill

Greenlee / A Textron Company

4455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

7

Inspection

Clean all parts with an appropriate cleaning solution

and dry them thoroughly. Inspect each component as

described in this section. Replace any component that

shows wear or damage.

1. Rotary Impact Assembly: Inspect the exterior for

damage and loose or missing parts. Inspect the

spur gear (through the small view hole in the end of

the mechanism) for grooves, nicks and chips. If the

unit is damaged, replace the impact assembly.

2. Bearings: Insert shaft into bearings. Spin shaft. If

the shaft does not spin smoothly, replace the entire

assembly with bearings already pressed in.

3. Motor Cap, Handle, and Adapter: Inspect mating

surfaces, bores, oil passageways, etc. for grooves

or nicks. If any component shows wear or damage,

replace the entire assembly with bearings already

pressed in.

4. Planet Gear with Needle Bearings: Insert a corre-

sponding dowel pin into the bearing. While holding

the dowel between a thumb and forefinger, roll the

gear in the palm of your other hand. If either gear

does not spin smoothly, replace both gears with

bearings already pressed in.

5. Inspect all other disassembled components for

cracks, grooves or nicks.

Assembly

Refer to the Illustrations and Parts Lists for correct

orientation and placement of parts.

Replace any O-rings, V-rings, seals, and gaskets on

parts that have been disassembled. Apply hydraulic

fluid or O-ring lubricant to all O-rings and all metal

surfaces which they must slide over. When installing

an O-ring which must slide over sharp surfaces, use a

rolling motion and be careful not to damage the O-ring.

Wherever the assembly results in metal-to-metal

contact, coat the surfaces with hydraulic fluid or O-ring

lubricant.

Some steps of the assembly procedure require a remov-

able type of thread sealing and locking compound, such

as Loctite

®

242 or equivalent. Follow the manufacturer’s

instructions for curing.

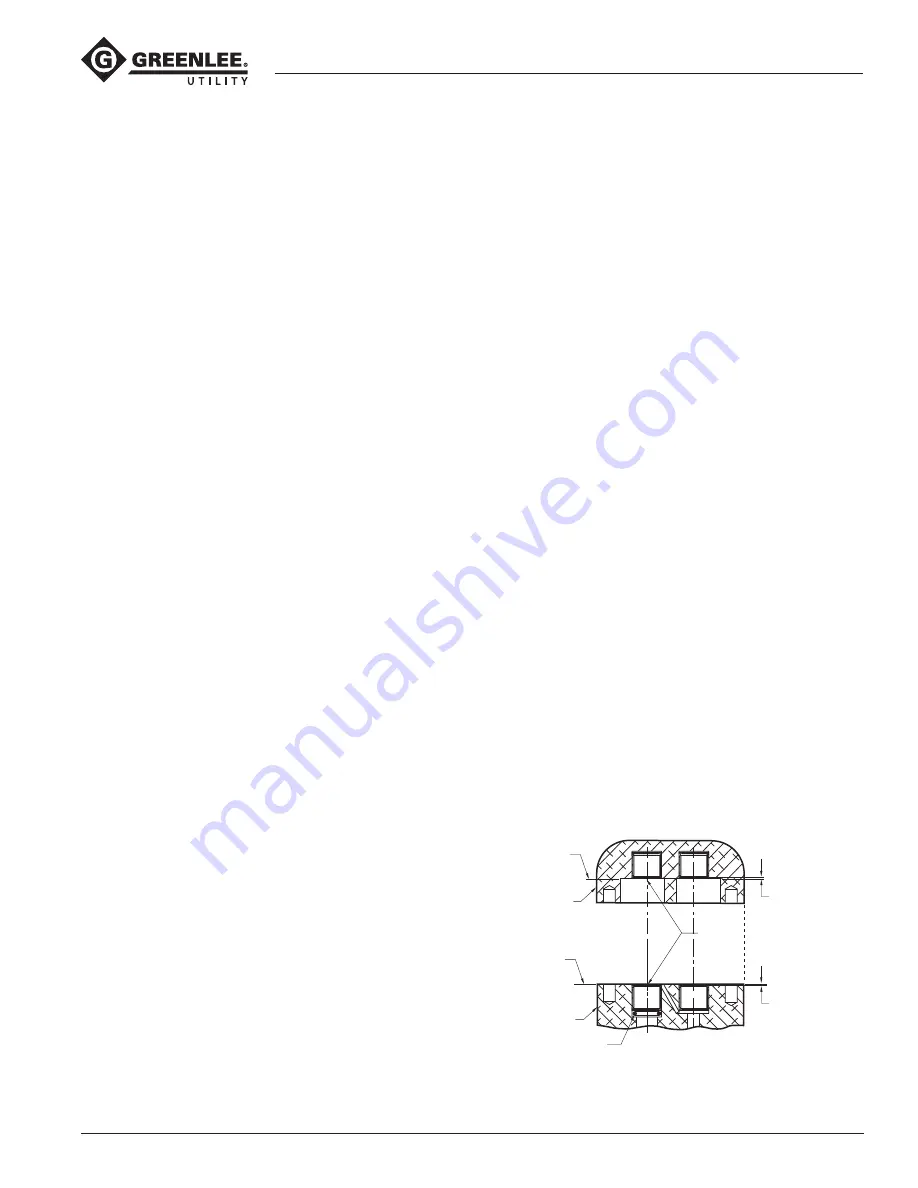

Needle Bearing Installation in Handle or Motor Cap

HANDLE:

1. Install a new needle bearing (3) with identification

mark facing up (readable from Surface A) into

the handle (1).

2. Press the bearing into the handle until the bearing

cage is 0.020 inch below Surface A.

3. Repeat the procedure for the other needle bearing if

it was removed.

MOTOR CAP:

1. Install a new needle bearing (48) with identification

mark facing up (readable from Surface B) into the

motor cap (47).

2. Press the bearing into the motor cap until the

bearing cage is 0.047 inch below Surface B.

3. Repeat the procedure for the other needle bearing if

it was removed.

Needle Bearing Installation

in Handle and Motor Cap

Surface B

Motor Cap

Surface A

Motor Body

O-ring Seal

Needle Bearing

0.020 below

Surface A

0.047 below

Surface B