GreenJet – Centrifugal Jet Fan

6

®

BMS Communication & Speed Control

RS-485 Communication

MODBUS follows a simple master/slave model. Slave

devices perform data read/write requests which are

issued from a client device such as a PLC or building

management system. Assignable addresses for server

devices range from an address of 1 to theoretical

maximum of 247. For a complete address list or motor

control questions, please contact Ziehl Abegg support

center at 336-834-9339. Default communication

parameters for serial MODBUS communication can be

found below.

MODBUS Read Communication

Input Register Address

Full Parameter Name

Parameter Setting

14

Speed

Decimal value 0-65535 RPM

15

Motor Current

Decimal value 0-65535 (in 0.01 A steps)

21

Line Voltage

Decimal value 0-65535 (in 1 V steps)

25

Motor Temperature

Decimal value 0-65535 (in 0.1 degrees C steps)

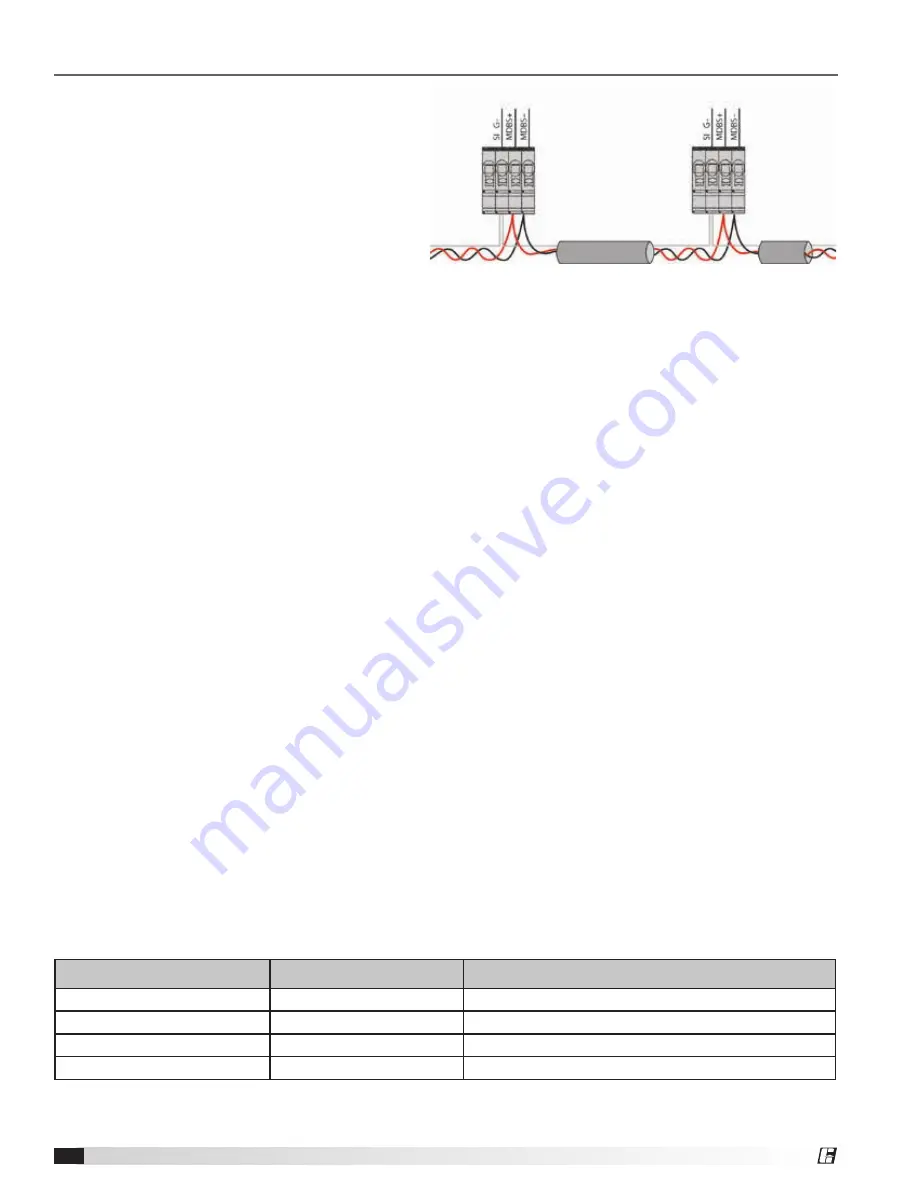

Figure 6 -

General example for MODBUS device

connection

Recommended Wire Types

1. CAT5 / CAT7 cables

2. J-Y (St) 2x2x0.6 (telephone wire)

3. AWG22 (2x2 twisted pair)

When using telephone flex with four cable cores, it is

recommended the following allocation:

“A (D+)” = red, “B (D-)” = black, “GND” = white

Pay attention to sufficient distance from power lines and

motor wires (min. 8 inches).

Max allowed wire length 3,280 feet (CAT5/7 500 m).

Networking via MODBUS-RTU

The device comes equipped with a RS-485 interface

for networking via MODBUS. Connection at: SI G-,

MDBS+1 and MDBS-1.

The address must be set in the IO Setup menu.

RS-485 - Network Design and Interface

Parameter

Ensure the correct connection; i.e. MDBS-1 must

always be connected to MDBS-1 of the next device.

The same applies to MD+1.

A “GND” connection must be established, as dissimilar

to potential (over 10V) will lead to the destruction of the

RS-485 interface (e.g. lightning).

Always use two wires of one lead (twisted pair) for

connection.

• COM Bus Address: 247

• COM Baud rate: 19200 Bd

• COM Mode: 8E1

• Bits = 8

• Parity = Even

• Stop bits = 1

• Handshake = None