If the engine is new, follow the engine manufacturer's

instructions to break-in the engine. After break-in,

confirm that the engine idles reliably, transitions smoothly

and rapidly to full power and maintains full power-

indefinitely. After you run the engine on the model, inspect

the model closely to make sure all screws remained tight,

the hinges are secure, the prop is secure and all pushrods

and connectors are secure.

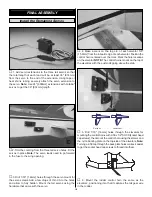

Ground check the operational range of your radio before the

first flight of the day. With the transmitter antenna collapsed

and the receiver and transmitter on, you should be able to

walk at least 100 feet away from the model and still have

control. Have an assistant stand by your model and, while

you work the controls, tell you what the control surfaces are

doing. Repeat this test with the engine running at various

speeds with an assistant holding the model, using hand

signals to show you what is happening. If the control

surfaces do not respond correctly, do not fly! Find and

correct the problem first. Look for loose servo connections or

broken wires, corroded wires on old servo connectors, poor

solder joints in your battery pack or a defective cell, or a

damaged receiver crystal from a previous crash.

Keep all engine fuel in a safe place, away from high heat,

sparks or flames, as fuel is very flammable. Do not smoke

near the engine or fuel; and remember that engine exhaust

gives off a great deal of deadly carbon monoxide. Therefore

do not run the engine in a closed room or garage.

Get help from an experienced pilot when learning to

operate engines.

Use safety glasses when starting or running engines.

Do not run the engine in an area of loose gravel or sand; the

propeller may throw such material in your face or eyes.

Keep your face and body as well as all spectators away from the

plane of rotation of the propeller as you start and run the engine.

Keep these items away from the prop: loose clothing, shirt

sleeves, ties, scarfs, long hair or loose objects such as

pencils or screwdrivers that may fall out of shirt or jacket

pockets into the prop.

Use a “chicken stick” or electric starter to start the engine.

Do not use your fingers to flip the propeller. Make certain the

glow plug clip or connector is secure so that it will not pop

off or otherwise get into the running propeller.

Make all engine adjustments from behind the rotating propeller.

The engine gets hot! Do not touch it during or right after

operation. Make sure fuel lines are in good condition so fuel

will not leak onto a hot engine, causing a fire.

To stop a glow engine, cut off the fuel supply by closing off

the fuel line or following the engine manufacturer's

recommendations. Do not use hands, fingers or any other

body part to try to stop the engine. Do not throw anything

into the propeller of a running engine.

Read and abide by the following Academy of Model

Aeronautics Official Safety Code:

1. I will not fly my model aircraft in sanctioned events, air

shows, or model flying demonstrations until it has been

proven to be airworthy by having been previously

successfully flight tested.

2. I will not fly my model aircraft higher than approximately

400 feet within 3 miles of an airport without notifying the

airport operator. I will give right of way to and avoid flying in

the proximity of full scale aircraft. Where necessary an

observer shall be used to supervise flying to avoid having

models fly in the proximity of full scale aircraft.

3. Where established, I will abide by the safety rules for the

flying site I use and I will not willfully and deliberately fly my

models in a careless, reckless and/or dangerous manner.

7. I will not fly my model unless it is identified with my name

and address or AMA number, on or in the model.

9. I will not operate models with pyrotechnics (any device

that explodes, burns, or propels a projectile of any kind).

1. I will have completed a successful radio equipment ground

check before the first flight of a new or repaired model.

2. I will not fly my model aircraft in the presence of

spectators until I become a qualified flier, unless assisted by

an experienced helper.

Radio Control

General

AMA SAFETY CODE (E

XCERPT

)

Failure to follow these safety precautions may result

in severe injury to yourself and others.

ENGINE SAFETY PRECAUTIONS

Range Check

Ground Check

23