For the best performance, the Li’l Poke must be built light.

One of the best ways to insure light weight is to build neatly

and make good-fitting glue joints. Here are some tips to help

you build neatly and light.

1. An accurate, easy way to cut balsa sticks is with a single-

edge razor blade. To do so, position the stick over the plan

or glue joint, then align the razor blade on the stick where it

is to be cut.

2. Press down lightly on the razor blade to make a mark.

Take the stick off the plan and cut it over a cutting mat or a

scrap piece of wood. (

With care, the stick could be cut on

the plan, but cutting through any protective covering on the

plan may cause the assembly to stick to the building board).

3. To avoid splitting the 1/8" x 1/8" [3.2 x 3.2mm] balsa

sticks used in the Li’l Poke, only small T-pins (HCAR5100)

or small pins found in craft stores should be used for

building this model. Do not stick pins into the sticks near the

ends, or the wood may split.

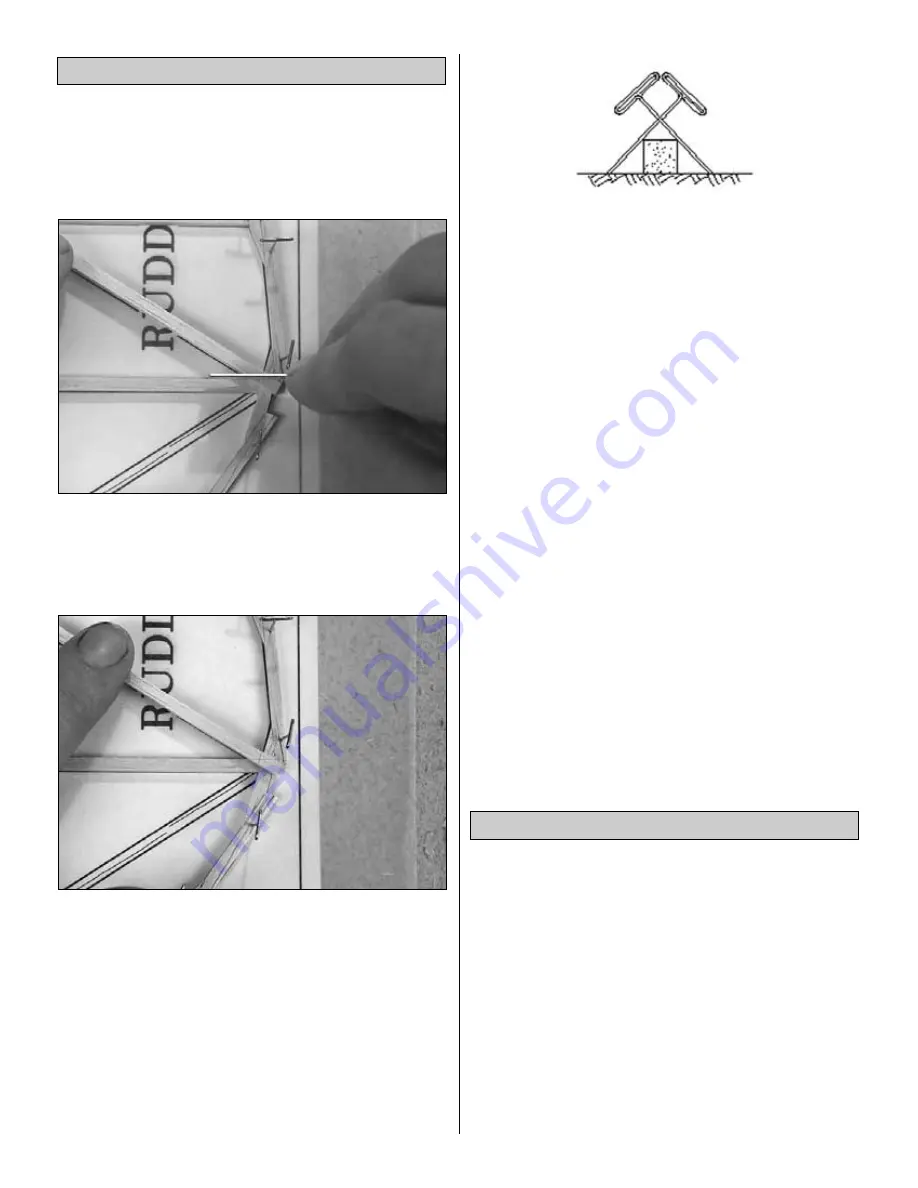

4.

An alternate method to sticking pins directly through

balsa sticks is to use the “crossed-pin” technique by

inserting pins into the building board over the sticks in a

criss-cross fashion.

5. Only a small amount of CA should be used to glue the

parts together. In addition to unnecessary weight, excess

hardened CA is difficult to sand. Use the included CA

applicator tips to control and pinpoint the amount of CA that

comes from the bottle. When the tip becomes clogged, cut

the tip off and continue. If additional CA tips are required,

order number GPMR6033 (5).

6. When applying CA, be careful to not glue your fingers to the

structure. In the process of

unsticking fingers you can

inadvertently damage the structure, thus requiring repairs and

adding additional weight

(not to mention the aggravation!).

7. Sanding requires a light touch to avoid damage. The best

method for sanding is to use light strokes in the direction of

the longest sticks. Be certain the sandpaper is

thoroughly

bonded to the bar sander. Lifted edges may catch the

structure. Use medium-grit sandpaper such as 120 or 150.

8. One of the best ways to insure a lightweight model is to

proceed slowly and

build neatly

. Good glue joints are

stronger, lighter and have a better appearance than poor-

fitting joints with too much CA. Of course, this approach

should be taken with

all

of your projects!

9. Work over a flat surface. Cover the plans with Great

Planes Plan Protector (GPMR6167) or wax paper so the

parts will not adhere to the plan.

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

15" = 381mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762mm

36" = 914.4mm

1" = 25.4mm (conversion factor)

Metric Conversions

IMPORTANT BUILDING NOTES

5