❏ ❏

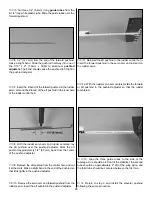

14. From the remaining 1/16” balsa STTRF02 laser-cut

sheet, cut two

wing tip braces

5/16” x 6-1/8” (7.9mm x

155.5mm). Glue the wing tip brace on the inside of the W-1

wing tip rib. The wing tip brace should be centered on the

aft edge of the leading edge dowel, between the wing spars

and the trailing edge sheeting.

❏ ❏

15. Remove the wing from your building board and

carefully sand off any excess glue. From the remaining 1/32" x

3" x 15" (.8mm x 76.2mm x 381mm) balsa sheet, cut pieces to

make bottom center sheeting to fit between the leading edge

dowel and wing spar and from the wing spar to the trailing edge

sheet. Glue the sheets in place and sand carefully.

❏ ❏

16. Cut and sand the wing spars and trailing edge

sheeting flush with the wing tip rib.

❏

17. Now go back to step 2 and build the right wing panel.

Remember!

Build it over the right wing plan.

❏

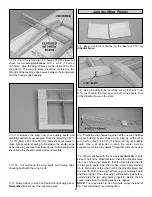

1. Draw a vertical centerline on the laser-cut 1/16" ply

dihedral brace

.

❏

2. Using a hobby knife, carefully cut a 1/16" slot in rib

W1A, just behind the main spar on both wing panels. Trial

fit the dihedral brace in the slots.

❏

3. Trial fit the wing halves together. With one wing half flat

on your building board, block-up the wing tip of the other

wing half so that it is 4-1/2" (114.3mm) off of your building

board. Use a sanding bar to sand the center joint as

necessary until the wing halves fit together without any gap.

❏

4. When satisfied with the fit, apply

medium CA

to both

sides of half of the dihedral brace. Insert the dihedral brace

into one of the wing halves so that the brace is attached to

the two main spars. After the CA has cured, apply medium

CA to both sides of the other half of the dihedral brace and

the root rib. With one wing half flat on your building board

and the wing tip of the other wing half blocked up as before,

quickly slide the two wing halves together. Before the CA

cures, make sure the trailing edges are aligned.

NOTE

: You may prefer to use 6-minute epoxy instead of

CA. This will allow more working time.

Join the Wing Panels

11

Summary of Contents for BLT

Page 24: ...TWO VIEW...