❏ ❏

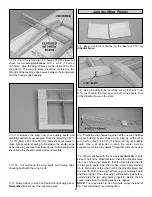

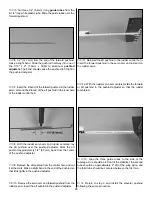

7. Position the top 1/8" x 1/4" x 24" (3.2mm x 6.4mm x

609.6mm) balsa main spar in the rib notches with one end flush

with the outside edge of the root rib and glue to all the ribs.

❏ ❏

8. Cut one of the 1/8" x 24" (3.2mm x 609.6mm)

hardwood dowels so that it fits in the notches at the front of the

wing ribs, from the root to the tip rib. Glue the dowel to the ribs.

Save the excess dowel for use as a wing hold down dowel.

❏ ❏

9. To make a

top trailing edge sheet

, draw a line 1/16"

(1.6mm) from the edge of a second 1/32" x 3/4" x 24" (.8mm

x 19mm x 609.6mm) balsa sheet. Sand a taper along the

edge up to the line. The sheet should fit in the notches at the

trailing edge of the wing ribs and blend into the bottom

trailing edge sheet.

Hint:

To avoid breaking the trailing edge sheet when

sanding the taper, sand across the grain, not lengthwise.

❏ ❏

10. Glue the top trailing edge sheet to the top of the

wing ribs and the aft edge of the bottom trailing edge sheet.

❏ ❏

11. From a 1/32" x 3/4" x 24" (.8mm x 19mm x

609.6mm) balsa sheet, cut and glue

shear webs,

horizontally, to the top and bottom spars in the locations

shown on the plan. Make sure they are glued securely to the

wing spars and ribs.

Do not install shear webs in the rib

bay between the W1A ribs.

❏ ❏

12. From a 1/32" x 3" x 15" (.8mm x 76.2mm x 381mm)

balsa sheet, cut pieces to make the

top center sheeting

to

fit between the wing spar and trailing edge sheet and

between the wing spar and the leading edge dowel. When

satisfied with the fit, apply medium CA to the top of the W1A

ribs and press the sheet in place. Hold the sheet in position

until the CA cures.

❏ ❏

13. Carefully sand the top center sheeting flush with the

wing spar, leading edge dowel and trailing edge sheet.

10

Summary of Contents for BLT

Page 24: ...TWO VIEW...