Great Plains | 151-144U | 2019/03/14

38

3P1006NT

Table of Contents

Index

Maintenance

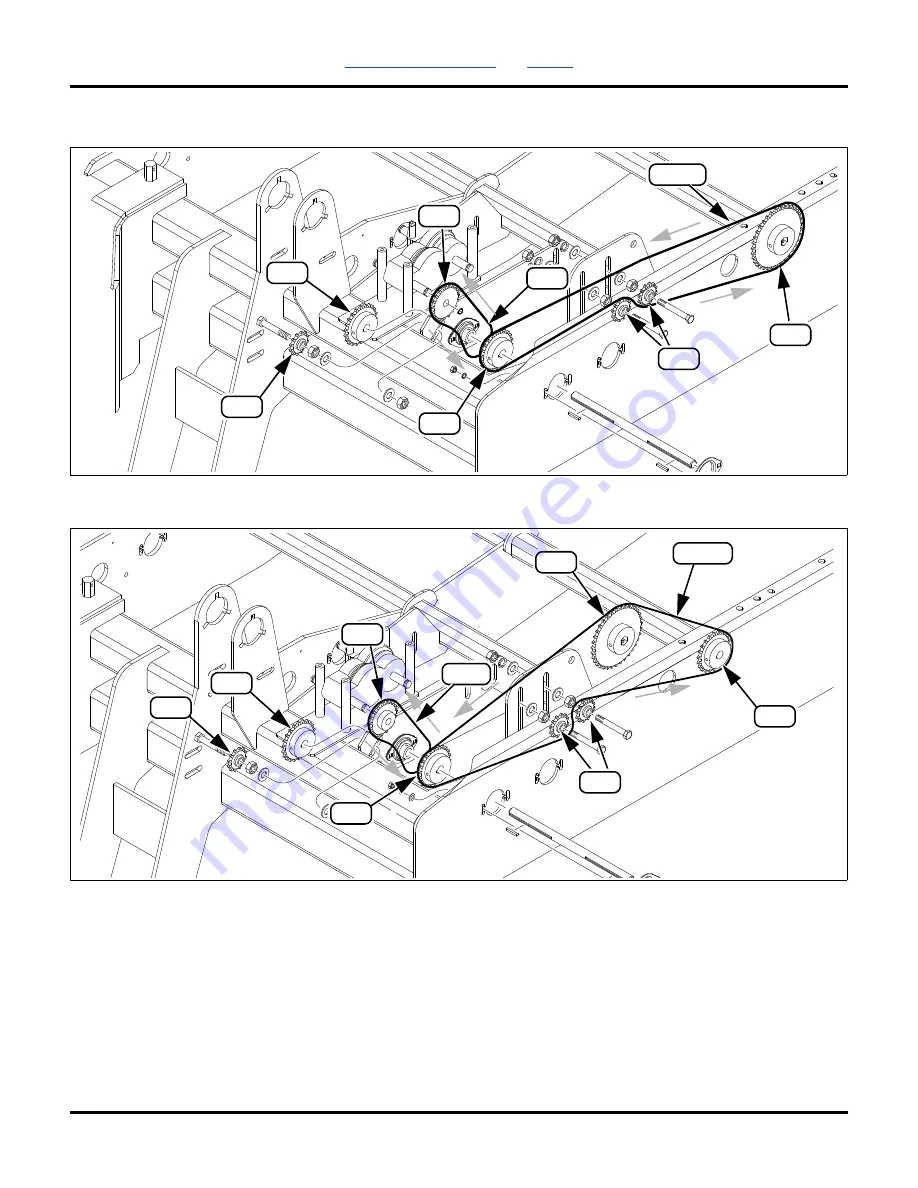

Main Seed Box Agitator (Option)

No fertilizer or small seeds is installed.

Agitator and Fertilizer Drive

No small seeds is installed.

22T

112P

28301

12i

12T

17T

40P

35T

12i

140P

28331

28T

35T

17T

12T

22T

12i

12i

40P