SignJet JS310 Series Set Up Guide

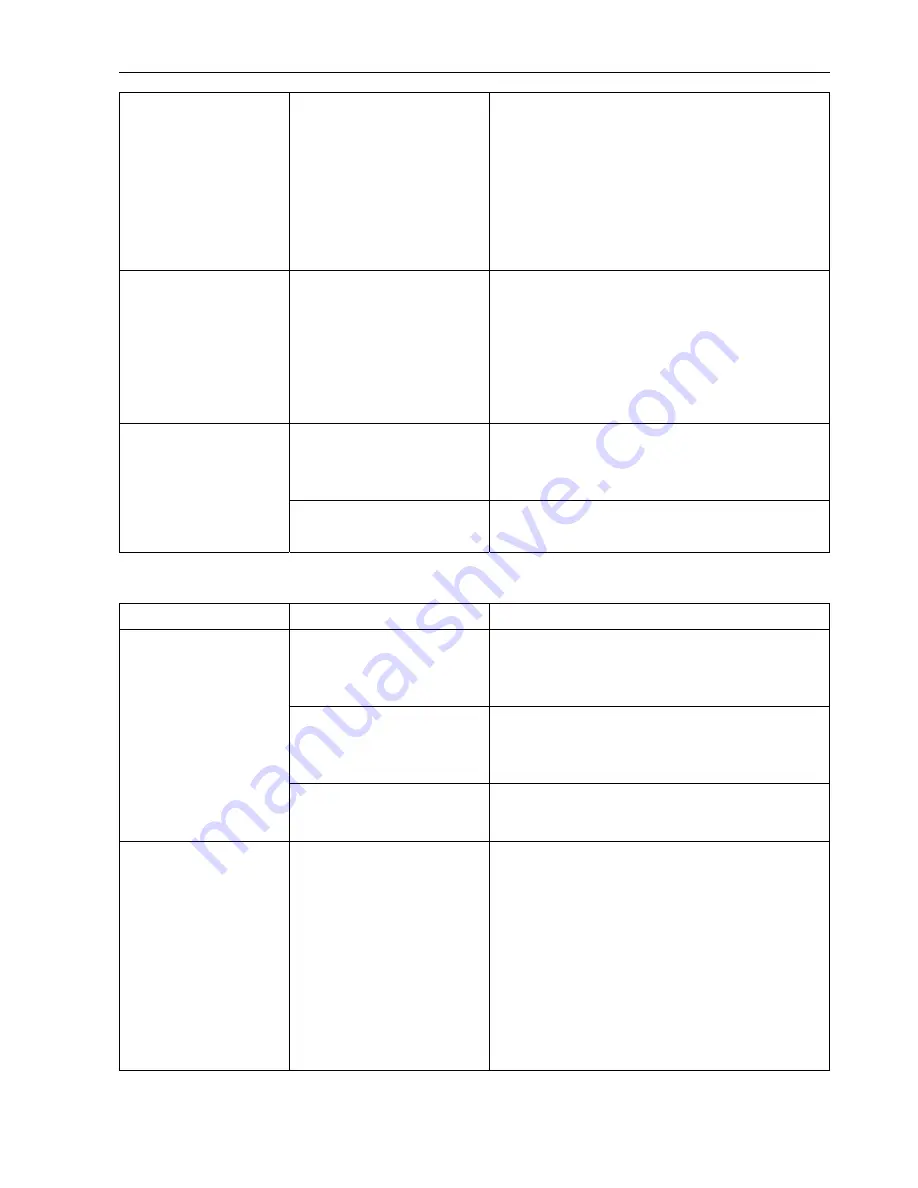

The images overlap.

The bi-directional band

adjustment is incorrect.

Perform the bi-directional band adjustment

procedure (See section

VII.10 Bi-directional

Printing Band Adjustments

).

If you replace the media with a different type,

adjust the height of the printheads or change the

printhead carriage speed, this adjustment

procedure must be performed.

There is a lot of blurring

on the image.

The heater setting value is

too low.

Blurring will occur if the heater setting value is too

low for the media being used. Raise the setting

value.

If phenomena such as the media shifting occur

and the heater setting value cannot be increased,

lower the printhead carriage speed.

The media feed motor is not

operating.

Check the selector switch on the media feeding

system and the direction selector switch setting

(See section

VI.1 Media Loading Procedure

).

The media cannot be

fed at all.

The press rollers are raised. Lower the press roller control pole.

■

Cleaning cannot be performed

Symptom Cause

Corrective

measure

Insufficient cleaning solution

in the solution tank.

Check the level of the cleaning solution in the

solution tank. If it is low, add some more cleaning

solution.

The 3-way valve for the

cleaning solution tank is

shut off.

Move the lever on the 3-way valve to the supply

position.

The cleaning solution is

not being fed.

There is a bend somewhere

in the ink supply tube.

Straighten out the bend.

Ink is being fed instead

of cleaning solution.

The tubes have been

connected incorrectly.

Check whether the ink tank and solution tank

tubes have been connected correctly.

If they have been connected incorrectly, clean all

the solution tank tubing and the incorrectly

connected ink tank tubing, and then feed cleaning

solution and ink through them once again as

appropriate.

Do not mix contaminated cleaning solution with

fresh cleaning solution.

- 80 -