2-2

Setting up The Cutter Plotter

2.1

Connecting to Your Computer

The cutting plotter can be connected to a computer via the serial (RS-232C) port or USB port. Select which

port to use according to the requirements of your application software and/or which of your computer's

interface ports are available for use.

Use a Centronics-compatible serial cable or USB cable in accordance with the connection method chosen.

Obtain a Graphtec approved interface cable that is compatible with the interface ports (the interface cables

are available separately).

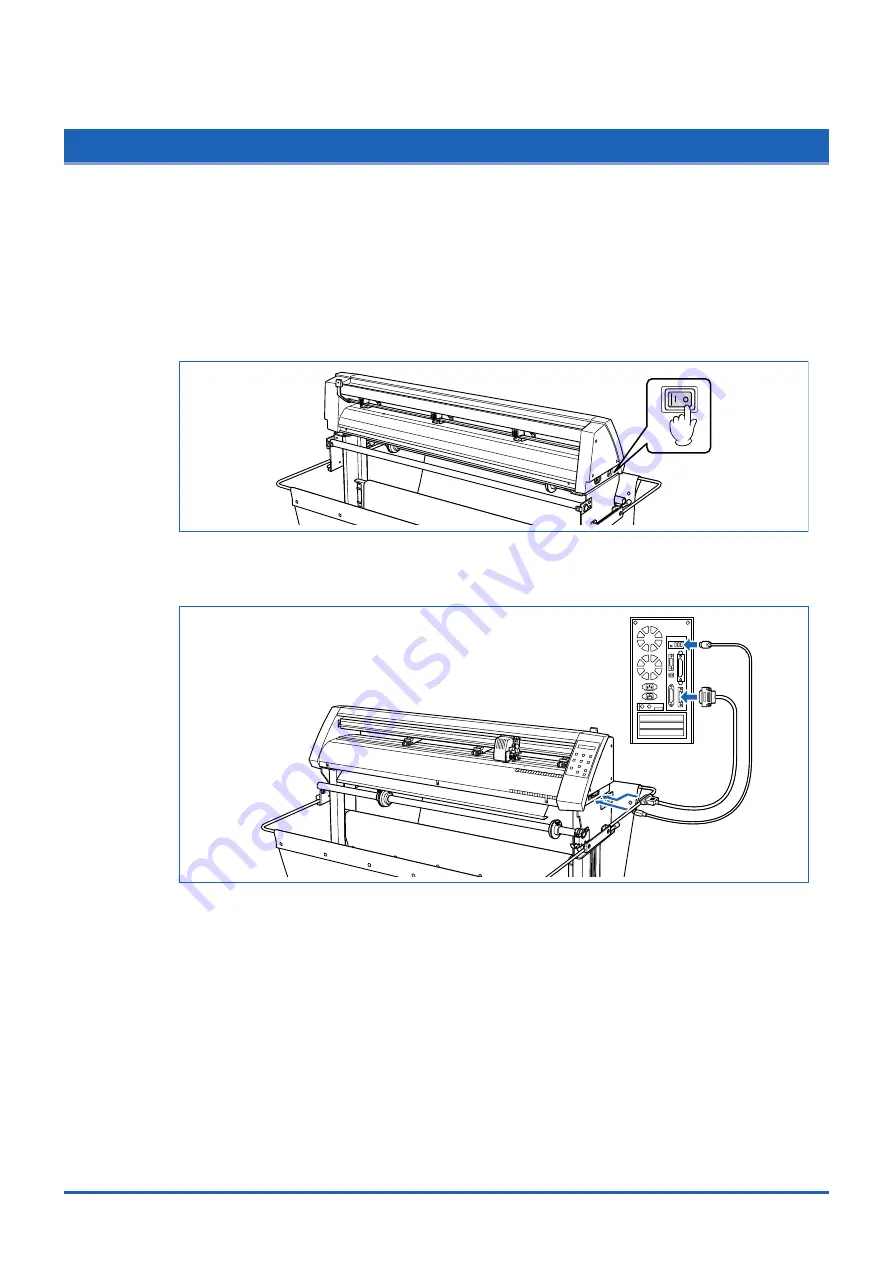

(1) Check to confirm that the Power switch is turned off (the "O" side is down).

(2) Connect the cable between the cutting plotter and the computer. Make sure the connectors at

the cutting plotter and computer ends are correctly oriented.