How to Spray

3A7656C

17

How to Spray

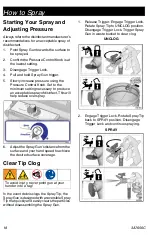

Choose Your Spray Tip

Your sprayer comes with 3 Spray Tip sizes:

Select the appropriate Spray Tip size to

provide the acceptable spray of disinfectant.

Refer to the disinfectant label for

manufacturer’s recommendations.

To prevent Spray Tip leaks, make certain

Spray Tip and Spray Tip Guard are installed

properly.

1.

Perform

2.

Use Spray Tip (A) to align gasket and

seal (B) in the Spray Tip Guard (C).

3.

Insert Spray Tip into Spray Tip Guard.

Verify Spray Tip is forward in the SPRAY

position.

4.

Screw Spray Tip Guard assembly onto

Spray Gun and tighten.

Use only disinfectants approved for

spray application.

Fumes from disinfectants with alcohol

active ingredients, or from other

flammable disinfectants, can explode or

ignite

. Pump motor generates sparks. To

prevent fumes from exploding or igniting:

•

Keep pump at least 20 ft from spray

area.

•

Do not spray pump.

•

Keep spray area well-ventilated.

•

Keep a good supply of fresh air moving

through the area.

To avoid serious injury from skin injection,

do not put your hand in front of the Spray

Tip when installing or removing the Spray

Tip and Spray Tip Guard.

Fine

LP617

Medium

LP619

Coarse

LP621