Technical Data

34

310645H

Technical Data

*Measured while spraying at 1 m.

#Measured per ISO-3744

Maximum working fluid pressure

100 psi (6.9 bar)

Maximum working air pressure

45 psi (3.1 bar)

Material pressure operating range

0-100 psi (0 to 6.9 bar)

Compressor

Type

Oilless

Air delivery

6.5 CFM @ 40 psi (184.1 lpm @ 2.8 bar)

Motor

120V, 60 Hz 15A

230V, 50 Hz 10A

Hopper capacity

15 US gallons (57 liters)

Maximum delivery with texture material

2.0 gpm (7.57 lpm)

Dimensions

Length

27 in. (685.8 mm) with handles

Width

26 in. (660.4 mm)

Height

40 in. (1016 mm)

Weight

With hoses and gun

147 lb (66.68 kg)

Without hoses and gun

131 lb (59.47 kg)

Wetted parts

PVC, Buna-N, anodized aluminum, powder coat

aluminum, brass, polyethylene, SST, UHMW

Sound data

Sound pressure level*

85.8 db(A)

Sound power level#

100.1 db(A)

Generator (minimum size requirement)

7500W (7.5 kW)

Maximum external working air pressure (must use

External Air Hookup Kit 287328 ONLY)

120 psi (8.3 bar)

Summary of Contents for RTX 1500 248201

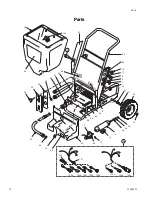

Page 30: ...Parts 30 310645H Parts TI A ...