Maintenance

6.

6

.

1.Printer Cleaning

To ensure the printing quality, please proceed this maintenance section to keep your printer

in good conditions and extend its life as well.

Please use one of following material to clean the printer.

★

Cotton swab

★

Lint-free cloth

★

Vacuum / Blower brush

★

100% ethanol

2.The cleaning process is described as following

:

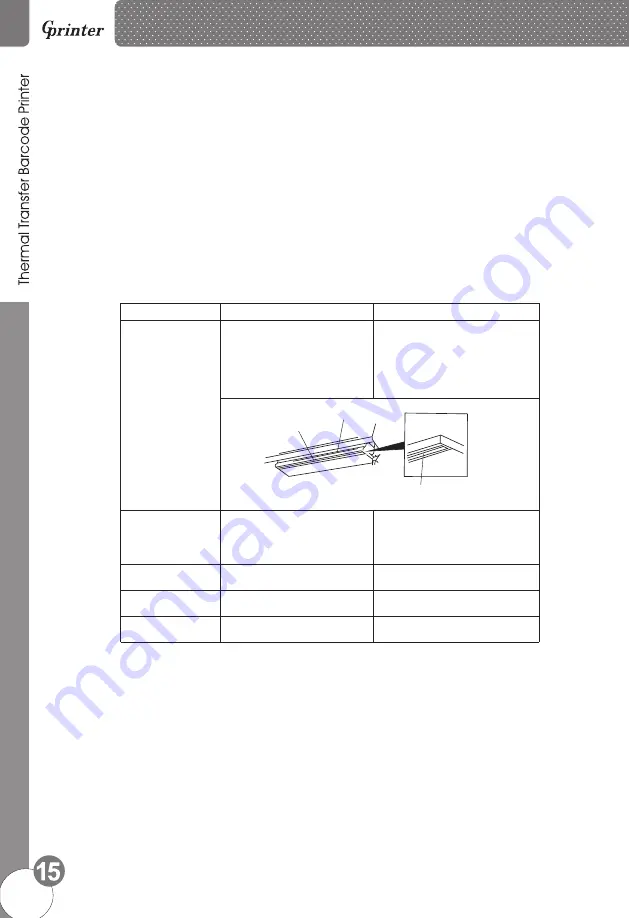

Parts

to

be

cleaned Step

Recommend cleaning frequency

head

Rubber roller

Paper

tear

bar

Sensor

Inner

side

of

printer

1.Turn off the printer.

2.Allow the print head to cool for

at least one minute.

3.Use a cotton swap and 100%

ethanol to clean the print head

surface.

When change new label paper

Thermal transfer printing head

Thermal transfer

printing head

Direct thermal printing head

Direct thermal printing head

1.Turn off the printer.

2.Rotate the platen roller and use

a cotton swap to clean with

100% ethanol.

When Change new label paper

Use a cotton swap and 100%

ethanol to clean.

When necessary.

When necessary.

Use air brush or vacuum to clean

dust of sensor.

Monthly.

Use air brush or vacuum to

the dust.

clean

Note

:

※

Always turn off the printer power before cleaning the printer.

※

Do not touch print head by figure.

※

Please use 100% ethanol

,

Do

not

use

medical

alcohol

to

aviod damage

to print head.

Summary of Contents for GP-1624T

Page 17: ......