OM-06114

VGH SERIES

MAINTENANCE & REPAIR

PAGE E - 5

Disconnect the bypass pipe (8) at the couplings (5)

in the pump casing and seal flange (37).

Remove the hardware securing the pump casing

to the base. Wedge a block of wood under the

bearing housing (15) to support the housing when

the casing is removed.

Remove the hex nuts (7) and separate the pump

casing from the seal plate. Tie and tag any leveling

shims used under the casing mounting feet. Re

move the seal plate gasket (41) and clean the mat

ing surfaces.

Immobilize the impeller shaft (22). Remove the im

peller hardware (45, 46, 47 and 50). Using a soft‐

faced mallet, tap the impeller from the shaft. Retain

the impeller key (51). Inspect the impeller and re

place it if cracked or badly worn.

Wear Ring Removal

Inspect the wear rings (42 and 44) for excessive

wear or scoring. The wear ring (41) is secured in

the seal plate by the set screw (53) and a press fit. If

replacement is required, remove the set screw. Us

ing a small bit, drill two holes through each of the

wear rings horizontally, 180

_

apart. Use a chisel or

other suitable tool to complete the cuts through the

wear rings, and remove them.

Use caution

not to

damage the pump casing or seal plate when re

moving the wear rings.

Seal Removal

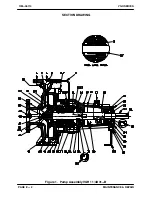

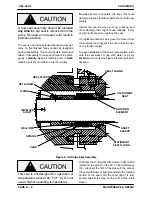

(Figures 1 and 2)

To remove the seal assembly (3), remove the nuts

(10 and 35) securing the seal plate (39) to the bear

ing housing (15) and seal flange (37). Slide the seal

plate and gasket (38) off the shaft (22).

Loosen the set screw (54) securing the shaft sleeve

(57) to the shaft. Slide the sleeve, seal assembly

and seal flange off the shaft as a unit.

Slide the shaft sleeve and rotating portion of the

seal out of the seal flange. Remove the O‐ring (40)

from the groove in the I.D. of the sleeve. Lubricate

the shaft sleeve with light oil and work it up under

the rubber bellows. Slide the rotating portion of the

seal off the shaft sleeve.

Unscrew the pin (11) and press the stationary seal

seat and O‐ring out of the seal flange.

If no further disassembly is required, see

Seal

Installation.

Shaft and Bearing Removal And Disassembly

When the pump is properly operated and main

tained, the bearing housing should not require dis

assembly. Disassemble the shaft and bearings

only

when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly‐

equipped shop by qualified personnel.

Remove the shaft key (56).

Remove the hardware (27 and 28) securing the

foot (29) to the base, and move the bearing hous

ing to a clean, well‐equipped shop for disassem

bly.

Remove the constant level oiler (18) from the bear

ing housing. Remove the drain plug (28) and drain

the oil from the bearing housing. Clean and rein

stall the drain plug.

Disengage the hardware (14 and 20) and remove

the inboard and outboard bearing covers (25 and

34) and gaskets (26 and 33). Inspect the oil seals

(23 and 32) and, if replacement is required, use a

screwdriver or other suitable tool to pry them from

the bearing covers.

Place a block of wood against the impeller end of

the shaft and tap the shaft and assembled bearing

(19) out of the bearing housing.

The inner ring for the roller bearing (31) will be re

moved with the shaft, while the outer ring and roll

ers will remain in the bearing housing. Press the

outer ring and rollers out of the bearing housing

from the back side. There are puller notches on the

back side of the inner ring. Use a suitable puller to

remove the inner ring from the shaft.

Remove the snap ring (24) and outboard bearing

spacer (21). Use a bearing puller to remove the