VGH SERIES

OM-06114

OPERATION

PAGE C - 2

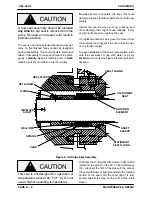

suction line and pump casing. To prime a pump

with a hand vacuum pump, open the cock on the

pump priming line. Operate the hand pump until

liquid flows out of the check valve on the bottom of

the primer pump. Once the pump is primed, close

the valve located between the primer and the

pump so that the prime will not be lost.

DRAIN

COCK

HANDLE

Figure 1. Hand Primer Assembly

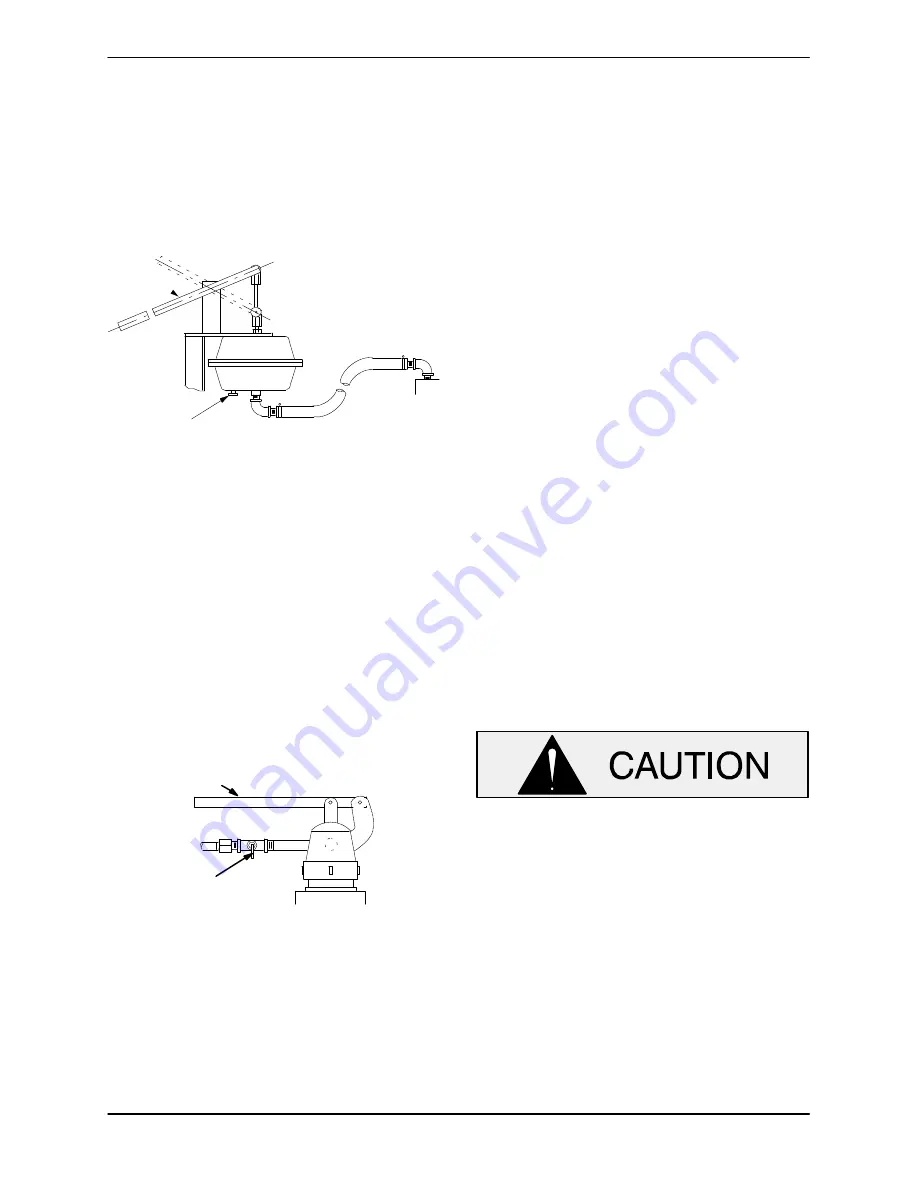

Exhaust Primers

Engine driven pumps normally take advantage of

the engine exhaust gases by using them to operate

an exhaust primer. The exhaust is directed through

a venturi which creates a vacuum in the pump cas

ing in order to fill the suction line and pump casing

with liquid. To prime a pump using an exhaust

primer, open the gas cock in the priming line and

engage the exhaust primer until liquid is thrown out

of the ejector nozzle.

GAS

COCK

HANDLE

Figure 2. Exhaust Primer Assembly

Air can be exhausted to prime a pump by using a

vacuum pump. Either a wet type or a dry type vac

uum pump may be used; however, a wet type is

preferred since it will not be damaged if liquid en

ters it. If a dry vacuum pump is used, provisions

must be made to keep liquid from entering it.

Auxiliary Ejectors

Ejectors function much like exhaust primers. They

may be operated by steam, compressed air, water

or exhaust gases. To prime a pump using an ejec

tor, open the gas cock in the priming line and oper

ate the ejector until liquid is thrown out the ejector

nozzle.

Vacuum Pumps

Air can be exhausted to prime a pump by using a

vacuum pump. Either a wet type or a dry type vac

uum pump may be used; however, a wet type is

preferred since it will not be damaged if liquid en

ters it. If a dry vacuum pump is used, provisions

must be made to keep liquid from entering it.

STARTING

Starting procedures will vary slightly depending on

the pump application, type of priming device, and

type of drive. Consult the operations manual fur

nished with the power source.

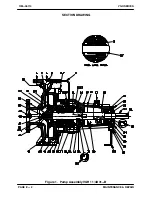

Rotation

The correct direction of pump rotation is indicated

by an arrow on the pump body or accompanying

decals. If the pump is operated in the wrong direc

tion, the impeller could become loosened from the

shaft and seriously damage the pump.

The pump must operate in the direction in

dicated by the arrow on the pump, or ac

companying decals. Reverse rotation

could loosen the impeller and seriously

damage the pump.

If the pump is driven by an electric motor, consult

the operating manual furnished with the motor be

fore attempting to start the motor.

If rotation is incorrect on a three‐phase motor, have

a qualified electrician interchange any two of the

three phase wires to change direction. If rotation is

incorrect on a single‐phase motor, consult the lit

erature supplied with the motor for specific instruc

tions.