GHS SERIES

OM-05450

PAGE E-5

MAINTENANCE AND REPAIR

pumps are equipped with drain plugs in the head

and backhead. Remove the plug(s) and drain the

pump before proceeding with disassembly.

Pressure Relief Valve (10)

If the pump is equipped with a pressure relief valve

(10A), it can be mounted on either the head assem

bly (01A) or the housing assembly (04). Some

models are equipped with one of each. Take note

as to the direction in which the relief valve is

mounted. To remove either style, remove the caps

crews (B) securing the relief valve to the pump. The

O‐rings (10C) may remain in the head (01A) or in

the housing (04A). Remove and discard the O‐

rings. For relief valve maintenance, see

RELIEF

VALVE DISASSEMBLY

followed by

RELIEF

VALVE REASSEMBLY

at the end of this section.

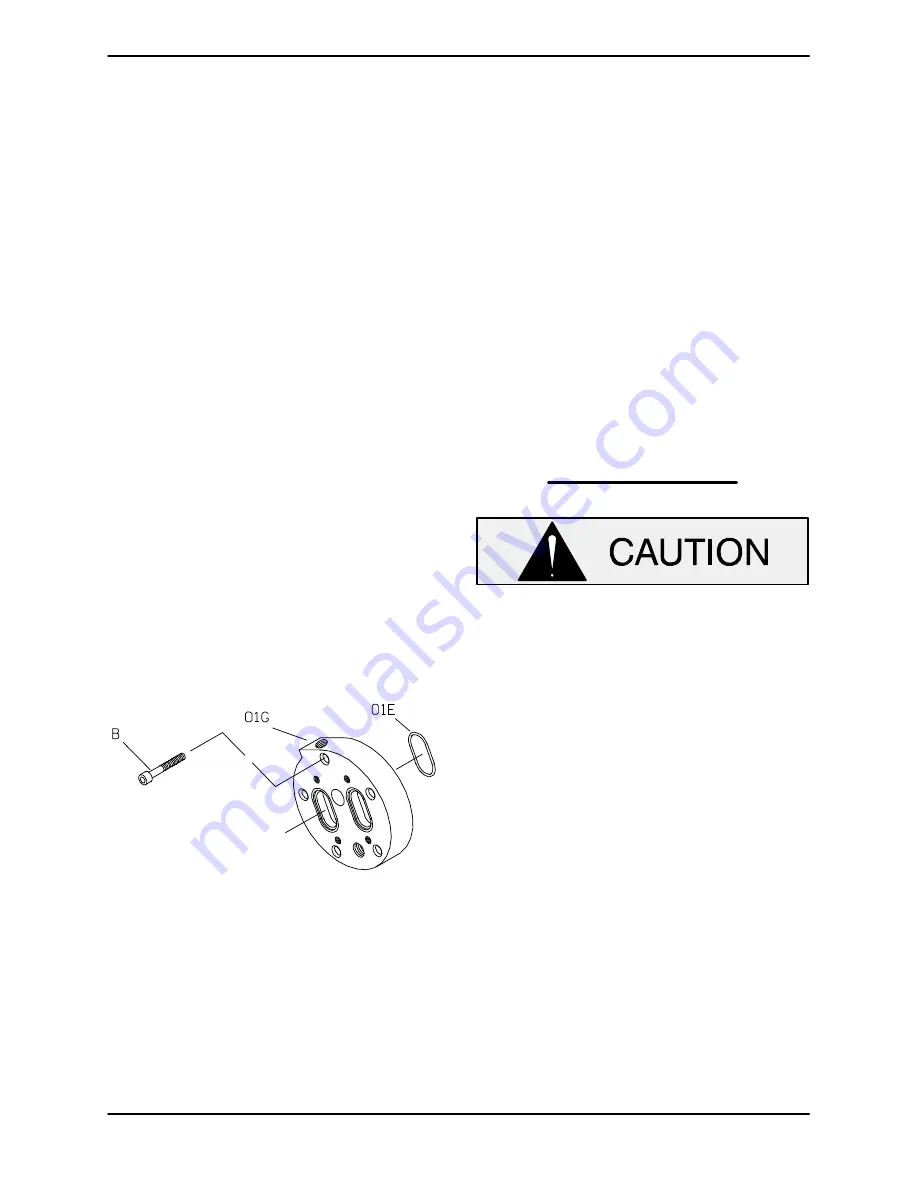

Optional Head Jacket

(Figure E‐1 And E‐2)

If your pump is equipped with an optional head

jacket, see Figure E‐2 and remove the capscrews

(B) securing the head jacket (01G) and O‐rings

(01E) to the head assembly (01A, Figure E‐1).

Figure E‐2. Typical Head Jacket Assembly

Rotor Adjusting Sleeve (07)

Before attempting to remove the bearing locknut

(03C), loosen the socket head setscrews (GA) se

curing the rotor adjusting sleeve (07) and use a

pipe wrench or other suitable tool to turn the rotor

adjusting sleeve clockwise (as viewed from the

drive end) until the rotor binds against the head.

This will prevent the rotor from turning as the lock

nut is unscrewed.

Straighten the tab on the bearing lockwasher (03B)

and use a hammer and drift pin to loosen the bear

ing locknut until it can be unscrewed from the

shaft. Remove the bearing lockwasher.

Unscrew the rotor adjusting sleeve kit from the

backhead.

NOTE

Part or all of the seal assembly (05) may be re

moved with the rotor adjusting sleeve. Check the

Parts List

furnished with your pump to identify the

seal, refer to

Seal Appendix

,

Section F

, for removal

of the seal and related components, then proceed

as follows with rotor adjusting sleeve disassembly.

When removing or installing the bearing

(07AC), never hit or press against the inner

race. Press

only

against the outer race.

Secure the rotor adjusting sleeve (07AA) in a vice

with the drive side down. Position a suitably sized

screwdriver horizontally through the slots in the

bearing retaining nut and use the screwdriver to

unscrew the bearing retaining nut from the rotor

adjusting sleeve. The bearing (07AC) is a light

press fit into the rotor adjusting sleeve and can

usually be removed with thumb pressure only. If

the bearing does not come out easily, use a suit

able sized sleeve and a mallet to lightly tap the

bearing from the bore.

Refer to

Cleaning and Inspection

in this section

before reassembling the rotor adjusting sleeve.

Coverplate Kit (11)

(Figure E‐1 And E‐3)

The coverplate kit may be mounted on either the

head assembly or the housing assembly. Removal

is the same for either.