STEP 2 - I-BEAM TO END SUPPORT WELDMENT CONNECTIONS

2.1

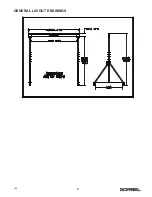

Assemble your Gantry Crane in a clear area free

of obstructions (refer to enclosed

General

Arrangement Drawing

for overall size and other

relevant dimensions).

2.2

Assemble the first end support assembly by fully

engaging the upper support weldment into the lower

support weldment such that the overall height is at

its minimum and the holes in both tubes are

correctly oriented relative to one another. Next,

slide assembly apart until the first hole in inner tube

is aligned with outer tube hole. Secure assembly

by inserting the hitch pin assembly through the

holes in both weldment tubes followed by

connecting the snap-on safety hair pin and small

cable (if provided by the manufacturer) to both

ends of the hitch pin. Ensure that the hitch pin

chains are located on the side of the end

support assembly that the eyebolt hole is on

(located on diagonal brace tube (as shown in

Diagram 2B

). Insert eyebolt into threaded hole

and attach chain with open-end chain link.

Repeat with the other end support assembly.

2.3

While resting on the floor tilt the I-beam (by

means of rigging (straps/slings are preferred to

reduce paint damage) that is sized and oriented

correctly for raising the load and overhead lifting

device or lift truck) so that the I-beam flange with

the holes is aligned with the top plate holes of

the first end support assembly (as shown in

Diagram 2A

).

2.4

Install the appropriate hardware (as shown in

Diagram 2C

).

Note:

Bevel washers are used with “S”

beams only. Tighten bolts (refer to

Chart 2A

for proper

torque rating). There must be a minimum of two threads

showing at the end of each bolt.

2.5

Install hoist or hoist trolley (by others) onto I-beam per

manufacturers specifications.

2.6

Repeat steps 2.3 and 2.4 with the other end support assembly.

TIP:

For easiest installation ensure that the end support

weldments are being supported while lying on their side

(as shown in

Diagram 2A

) prior to bolting the I-beam to

them.

TIP:

Be sure that the top plate (located on top of vertical

tubes) length is oriented parallel to the I-beam length.

Diagram 2A.

End Support Assembly.

Diagram 2B.

Hitch Pin Assembly.

Diagram 2C.

Beam to Top Plate Connection.

3

9/19

Chart 2A.

Torque Chart.

Bolt Dia.

Torque

1/2”

60 ft.-lbs.

5/8”

110 ft.-lbs.

3/4”

200 ft.-lbs.