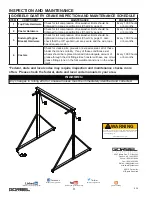

INSPECTION AND MAINTENANCE

*Federal, state and local codes may require inspection and maintenance checks more

often. Please check the federal, state and local code manuals in your area.

600 Fishers Run, P.O. Box 593

Fishers, NY 14453-0593

Phone: (800) 821-0086

Fax: (800) 828-1808

E-Mail: [email protected]

http://www.gorbel.com

© 2019 Gorbel Inc.

All Rights Reserved

9

9/19

WARNING

Any changes in rolling effort or unusual noises must be immediately identified and corrected.

GORBEL® GANTRY CRANE INSPECTION AND MAINTENANCE SCHEDULE

ITEM

COMPONENT

MAINTENANCE

FREQUENCY*

1

Top Plate Hardware

Check for full compression of lockwasher. Bolts should be

tightened to torque specifications (Chart 2A, page 3).

Every 1,000 hours

or 6 months

2

Caster Hardware

Check for full compression of lockwasher. Bolts should be

tightened to torque specifications (Chart 2A, page 3).

Every 1,000 hours

or 6 months

3

Endstop/Tagline

Bracket Hardware

Check for full compression of lockwasher. Bolts should be

tightened to torque specifications (Chart 2A, page 3). Also

check that the 3/8” eyebolt nuts are secure and the wire rope

has adequate tension.

Every 1,000 hours

or 6 months

4

Casters

Check for cracks, pits, grooves or excessive wear: all of these

hinder the crane’s mobility. If any of these conditions exist,

wheels should be replaced. Also add an adequate amount of

grease through the zirk fittings. Each caster will have one or two

grease fittings (one on the fork weldment and one on the wheel

itself).

Every 1,000 hours

or 6 months

Facebook.com/gorbelinc

Twi� er

twi� er.com/gorbelinc

linkedin.com/company/gorbel

youtube.com/gorbelmarke� ng

gorbel.com/blog

WARNING

This product can expose you to chemicals, including acrylonitrile,

which are known to the State of California to cause cancer. For

more information go to:

www.P65Warnings.ca.gov