INTRODUCTION

Thank you for choosing a Gorbel® Gantry Crane to solve your material handling needs. The

innovative design and heavy-duty construction of Gorbel® Adjustable Gantry Cranes will

provide a superior quality product. All Gorbel® cranes are pre-engineered for powered hoist

operation. The hoist weight allowance is 15% of the crane capacity (for example, a crane

rated for 1000 pounds, allows for a 1000-pound live load plus 150 pounds for the weight of the

hoist). There is also an allowance of 25% of the crane capacity for impact caused by hoist use.

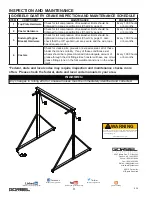

Gorbel® Gantry Cranes will provide many years of dependable service by following the

installation and maintenance procedures described herein.

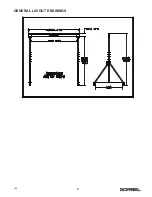

Dimensions contained in this installation manual are for reference only and may differ for

your particular application. Please refer to the enclosed General Arrangement Drawing for

actual dimensions.

Normal safety precautions:

These include, but are not limited to:

• Checking for obstructions in crane travel

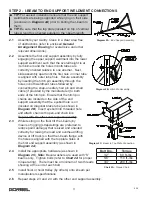

• Checking that all bolts are tight and have lockwashers

• Making sure that festooning cannot be snagged or pinched, whether it is electric or pneumatic

• Checking for any other unsafe conditions

• For additional safety precautions, see page 7

WARNING

Read all instructions in this manual before assembling or using this equipment.

WARNING

NEVER

exceed the rated capacity of the crane.

WARNING

A load should be moved from one point to another by moving the trolley back and forth along the

Gantry I-beam, while the Gantry Crane itself is stationary. Use

EXTREME CAUTION

and

CENTER THE LOAD ON THE I-BEAM

when attempting to horizontally move a load by moving

the entire Gantry Crane; this is

NOT RECOMMENDED

.

WARNING

NEVER

leave a suspended load unattended or walk under a suspended load. The equipment

must be operated from a position that will not be hazardous to the operator.

1

9/19

WARNING

With

ADJUSTABLE

Gantry Cranes, raise or lower the I-beam prior to attaching a load.

DO

NOT

raise or lower the I-beam with a load attached. Ensure that the hitch pin assemblies are

installed immediately (including the clip-on safety hair pins) after raising or lowering the crane to

the desired height and before removing the overhead lifting device or lift truck.