6.6 Ribbon shield settings

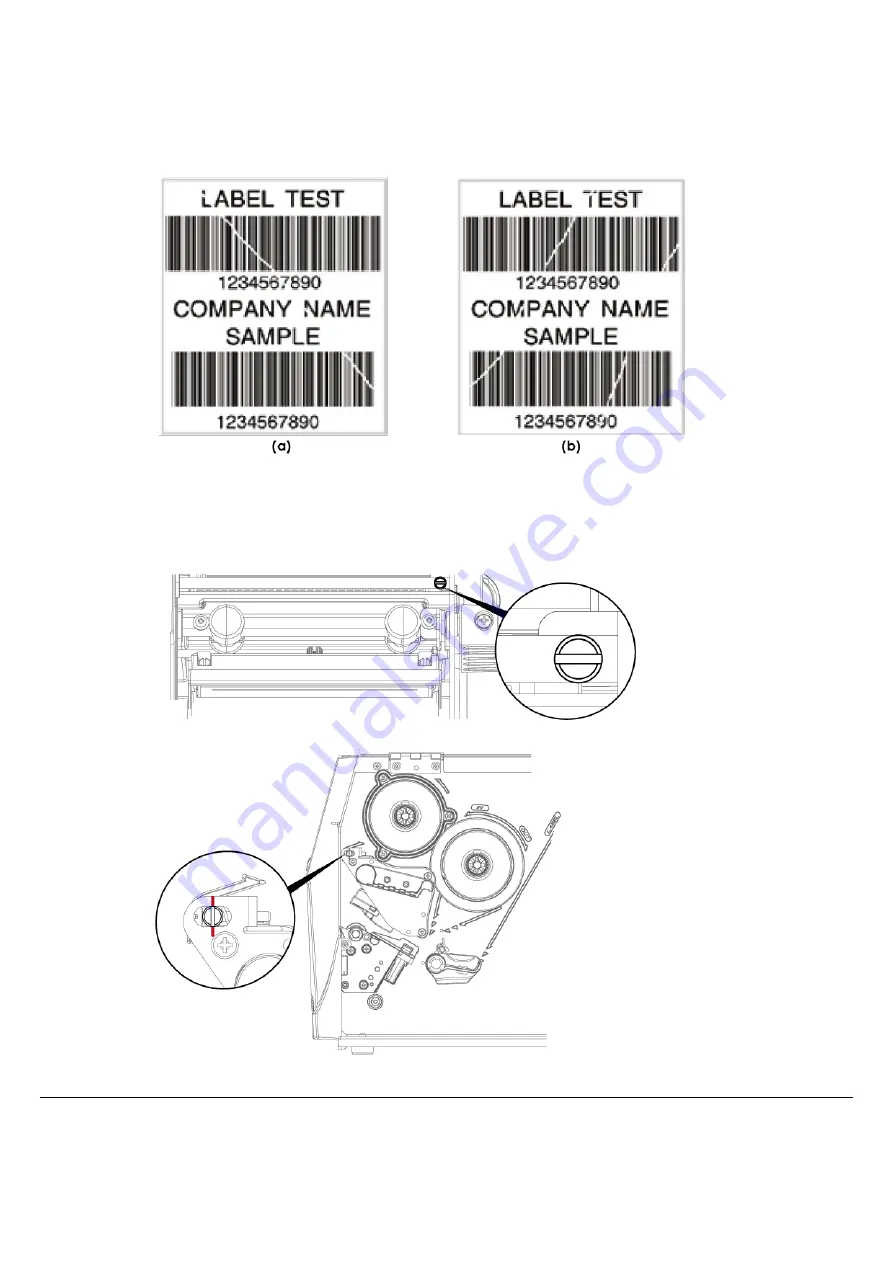

The use of different ribbon materials may cause wrinkling of the ribbon, which in turn affects the print result as illustrated by the examples in

(a) and (b). To change the print quality, you can adjust the ribbon shield screws.

If your print result looks like the example in (a), you need to turn ribbon shield screw counterclockwise.

If your print result looks like the example in (b), you need to turn ribbon shield screw clockwise.

To keep track of the change in print quality, you should adjust the screws by half a turn at a time.

Print a test page. If there is no improvement in the print result, turn the screw by another half turn.

Do not turn the adjustment screw more than two full turns(36

0

〫

).

Note

* If you adjust the screw by more than two full turns, the paper feed may no longer function correctly. In that case, unscrew the ribbon

shield screws to align the reset mark and restart the adjustment process.

Reset Mark

即可取出印

表頭