1. About the Printer

1-1. Introduction

The EZ-4TT/4TK Plus includes the following features:

The EZ-4TT/4TK Plus is a label printer capable of printing in both thermal transfer and direct thermal mode

for maximum versatility

EZ-4TT Plus has a 4” print wide with 16” print length that can be maximized to 40” long and the EZ-4TK

Plus has a 4” print wide with 6” print length that can be maximized to 16” long

The printing resolution is 203dpi / 300dpi and a high-speed performance of up to 4” per second

EZ-4TT/4TK Plus are the ideal printer for different project requirements due to its design of downloadable

firmware

The EZ-4TT/4TK Plus can also function without a PC as a stand-alone printer when connected to the

Godex user-friendly keyboard where space is limited

Built-in memory for download labels, pictures, ASCII bitmap fonts and Asia bitmap fonts

Y2K compliant Internal Time/Date clock can record the time automatically and functions when power is off

Large label roll size for 10 inches O.D. up to 260 meters in length.

Free QLabel-III software bundled in every printer package, thus providing a complete solution

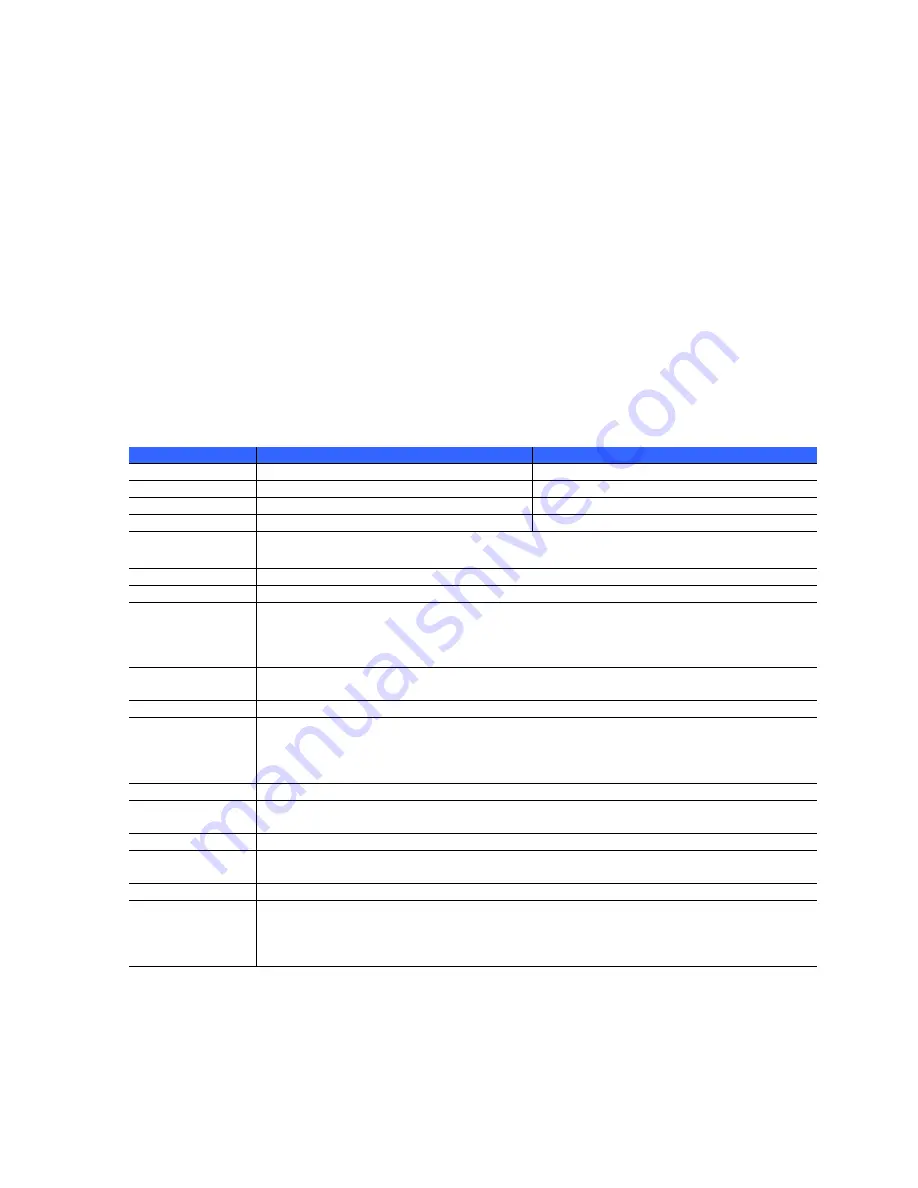

1-2. General Specifications

Specifications

EZ-4TT Plus

EZ-4TK Plus

Resolution

203 dpi

300 dpi

Print speeds

1” ~ 4”

2” ~ 4”

Print length

10mm~406mm

10mm~152mm

Print width

25mm~104mm

25mm~108mm

Media

Thickness: 0.06mm to 0.2mm

Roll size: Internal O.D. 4” / External O.D. 10” on a 1” or 3” I.D. core

Ribbon

Max.110mm width; 150 meters length; I.D. 0.5”

Memory

Fonts, Graphics, Formats and Double-byte characters storage

Programming

Godex EZPL Language (downloadable)

Label Create Software – QLabel-III

Windows Driver (31/95/98/ME/2000/NT)

DLL

Bar codes

Code 39, Code 93, Code 128 (A,B,C), UCC 128, UPC A / E (add on 2 & 5), I 2 of 5, EAN

8 / 13 (add on 2 & 5), CODABAR, POSTNET, EAN 128, DUN 14

2D Bar codes

MAXICODE, PDF417

Fonts

Internal CG Triumvirate fonts

Soft Fonts downloadable

All fonts in 4 directions rotation (0, 90, 180, 270 degrees)

Asia fonts in 8 directions rotation (left to right or top to bottom)

Graphics

BMP, PCX file; Support ICO, WMF, JPG, EMF file through software

Sensing

Sensor type: Label gap sensing, Black mark sensing

Detection: Label length auto sensing and/or Program Command setting

Real Time Clock

Standard

Interface RS-232

Centronics parallel

Power

Auto Switch AC110V~240V, DC24V5A

Environment

Operating Temperature: 40°F to 104°F (5°C to 40°C)

Operating Humidity: 30%-85%

Storage Temperature: -40°F to 122°F (-20°C to 50°C)

Storage Humidity: 10%~90%

3