Airmac Owner’s Manual

August 2006

© Glenco Manufacturing Pty Ltd

Page 35 of 44

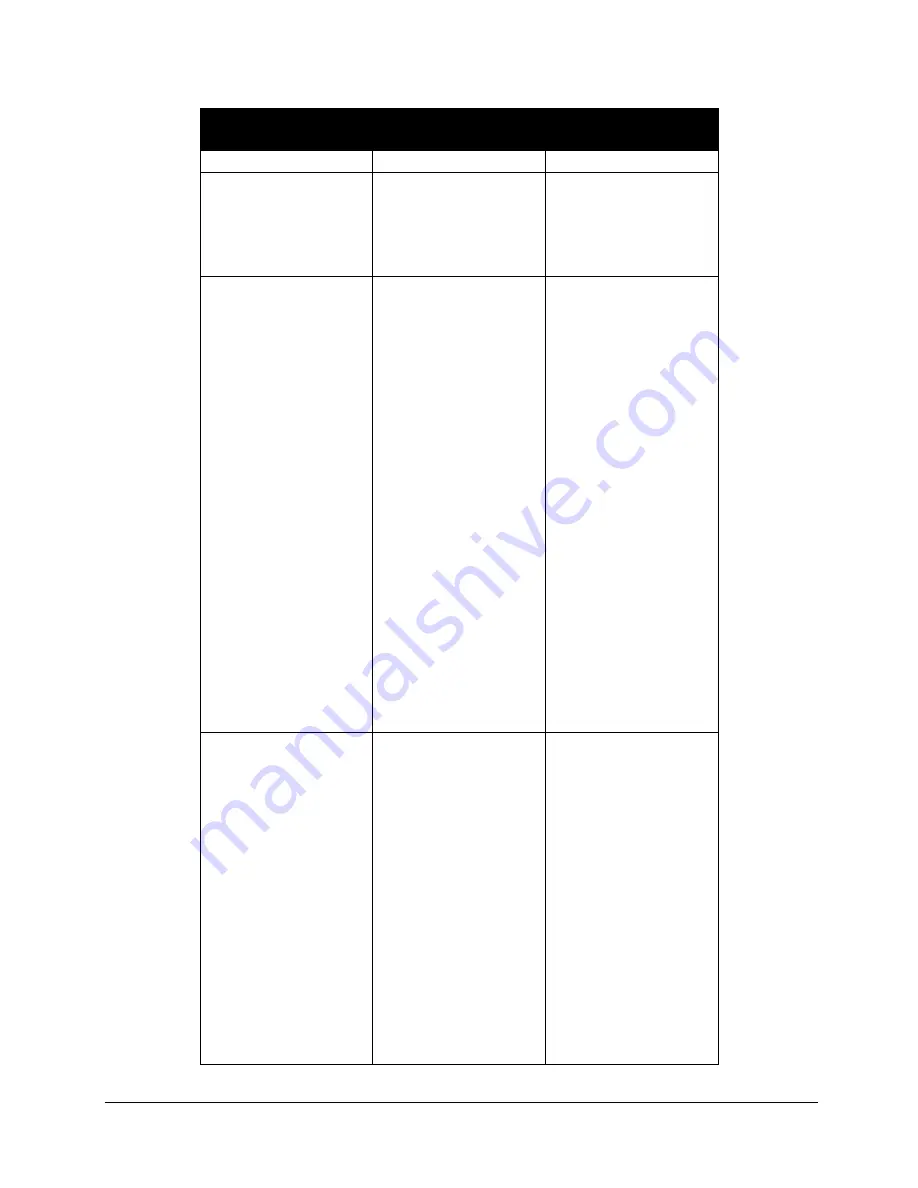

TABLE 5

TROUBLESHOOTING CHART

Symptom

Possible Cause

Corrective Action

compressor pump valves

and/or blown cylinder

head gaskets.

6. Compressor pump

partially seized.

pump valves and/or

cylinder head gaskets.

6. Repair or replace

compressor pump.

Excessive noise (including

knocking and rattling) or

vibration.

1. Loose engine/motor

and/or compressor

pulleys. V-belts too tight

or misaligned.

2. Low oil level.

3. Pistons hitting the cylinder

heads.

4. Damaged or worn

crankshaft bearings,

crankpin bearings,

crankshaft, connecting

rods, piston pin bearings,

piston pins, pistons,

cylinders and/or valves.

5. Faulty non-return valve.

6. Loose fasteners.

7. Engine fault.

1. Tighten or replace pulleys

as required, check

alignment and adjust V-

belt tension.

2. Add oil.

3. Remove cylinder heads

and check for carbon

deposits or other foreign

matter on top of pistons.

4. Replace components or

entire compressor pump.

5. Repair or replace non-

return valve.

6. Check and tighten

fasteners (including foot

mounts).

7. See engine manual.

Slow pressure rise or unable

to reach cut-out pressure.

1. Air demand exceeds

compressor pump

capacity.

2. Air leaks.

3. Blocked or dirty inlet air

filters.

4. Loose engine/motor

pulley, loose compressor

pump pulley, or

loose/worn V-belts.

5. Head unloaders not fully

retracting (usually

indicated by air blowing

out from air filter inlets).

1. Reduce air demand or

use larger or additional

compressor(s).

2. Tighten, refit or replace

leaking connections or

components.

3. Clean or replace air filter

elements.

4. Tighten or replace pulleys

as required, check

alignment and adjust V-

belt tension.

5. Repair or replace head

unloaders.