2

WIRING CONNECTIONS

NOTICE:

Clamp the power cable to prevent strain on the

terminal screws.

Refer to motor wiring diagram on pump motor for proper motor

wiring connection.

1. Install, ground, wire and maintain this pump in

compliance with the National Electrical Code (NEC) or the

Canadian Electrical Code (CEC) and with all local codes

and ordinances that apply. Consult your local building

inspector for local information.

2. Make sure that the voltage, frequency and phase (single

phase or three phase) of the power supply agree with that

stamped on the motor nameplate. If in doubt, check with

the power company.

3. Some models are equipped with three phase motors.

Three phase motors require magnetic starters and can

run in either direction, depending on how they are

connected to the power supply.

To Check For Proper Rotation – 3 Phase Motors

NOTICE:

Some models are equipped with three phase motors.

Three phase motors require magnetic starters and can run in

either direction, depending on how they are connected to the

power supply.

Risk of electrical shock.

1. Be sure power is disconnected to motor when working on

electrical connections.

2. Remove the cap over the motor shaft. Momentarily start

pump. If hookup is correct, the shaft will rotate clockwise.

3. If rotation is not clockwise, reverse any two leads to the

starter. The rotation will now be correct.

GROUNDING THE MOTOR

Ground the pump permanently using a wire of size and type

specified by local or National Electrical Code.

MAINTENANCE

Pump Disassembly

Hazardous voltage.

Can shock, burn or cause

death. Disconnect power to pump before servicing.

Tools required:

1. 7/16” open end wrench (2 required).

2. Flat blade screwdriver with insulated handle.

3. Work bench with vise recommended.

4. Pliers or similar tool.

5. Pipe wrench.

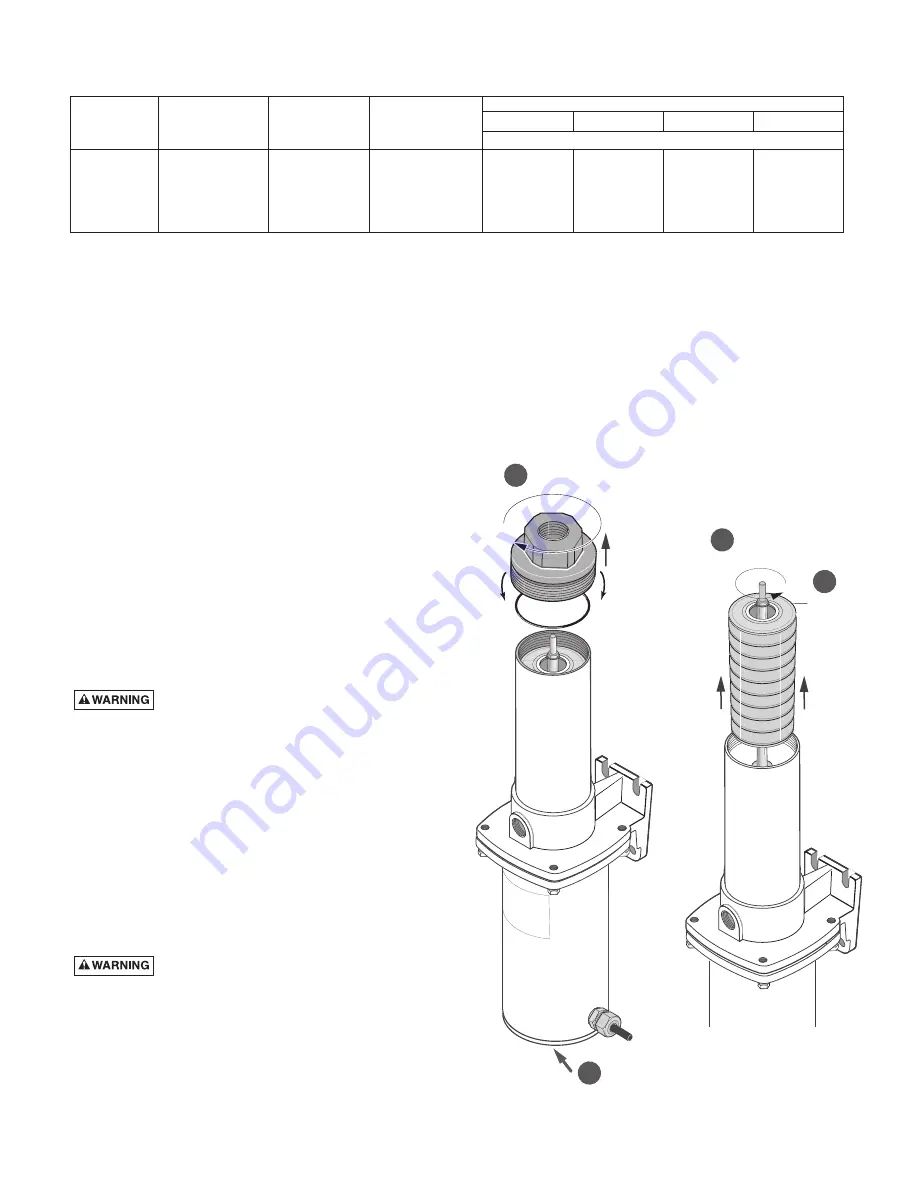

Impeller Stack Changeout

(See Figure 1)

Remove pump from service and mount vertically in vise (if

available) motor side down. Hold at center of motor. It may be

desirable to wrap motor with a shop rag to protect outside

surface.

Proceed as follows:

1. Attach pipe wrench to flats on discharge connection and

turn clockwise to remove (left hand threads).

2. Remove cap over shaft end. Hold shaft with a wrench on

the shaft flats.

Disconnect

from

po

w

er

so

u

rce.

Hold shaft flats.

2

Impeller

Stack

Snap

Ring

Remo

v

e

w

ith

Counter-clockwise

rotation.

3

4

1211 0

8

94 GS

1

Discharge

Connection

Remo

v

e

w

ith

clockwise

rotation.

Figure 1 – Impeller stack changeout.

TABLE I - RECOMMENDED FUSING AND WIRING

Wire Length

Motor

Volts/

S.F.

Branch Fuse

0’-50’

51-100’

101-200’

201-300’

H.P.

Phase

Amps

Rating Amps

AWG Wire Size

1

208-230/1

8.5-10.4

15

14

14

14

12

1

208-230/460/3

4.8/2.4

15/15

14/14

14/14

14/14

14/14

1-1/2

208-230/1

10.5-11.2

15

12

12

12

10

1-1/2

208-230/460/3

6.0/3.0

15/15

14/14

14/14

14/14

14/14