6

REPAIR INSTRUCTIONS - P200A-3100 SERIES

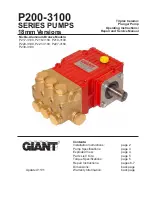

1. With a 22mm socket

wrench, remove the (3)

discharge valve plugs and

(3) inlet valve plugs (32)

Inspect the o-ring (33) for

wear and replace if dam-

aged.

2. Using a needle nose pliers,

remove the inlet and dis

-

charge valve assemblies

(27-30), for P230-3100 only,

remove spacer (30A), and

o-ring (31).

Inspect all parts

for wear and replace as nec-

essary.

3. By inserting a small screw

driver between the valve

seat (27) and the valve

spring retainer (30), the

valve assembly can be sepa-

rated.

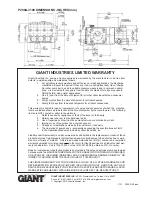

7. Remove the weep return

ring (25), pressure ring

(24), and v-sleeve (23)

from the valve casing (26).

Remove the rear v-sleeve

(23A) from the seal case

(20). Inspect all parts, in

-

cluding o-ring (21) for wear

and replace as necessary.

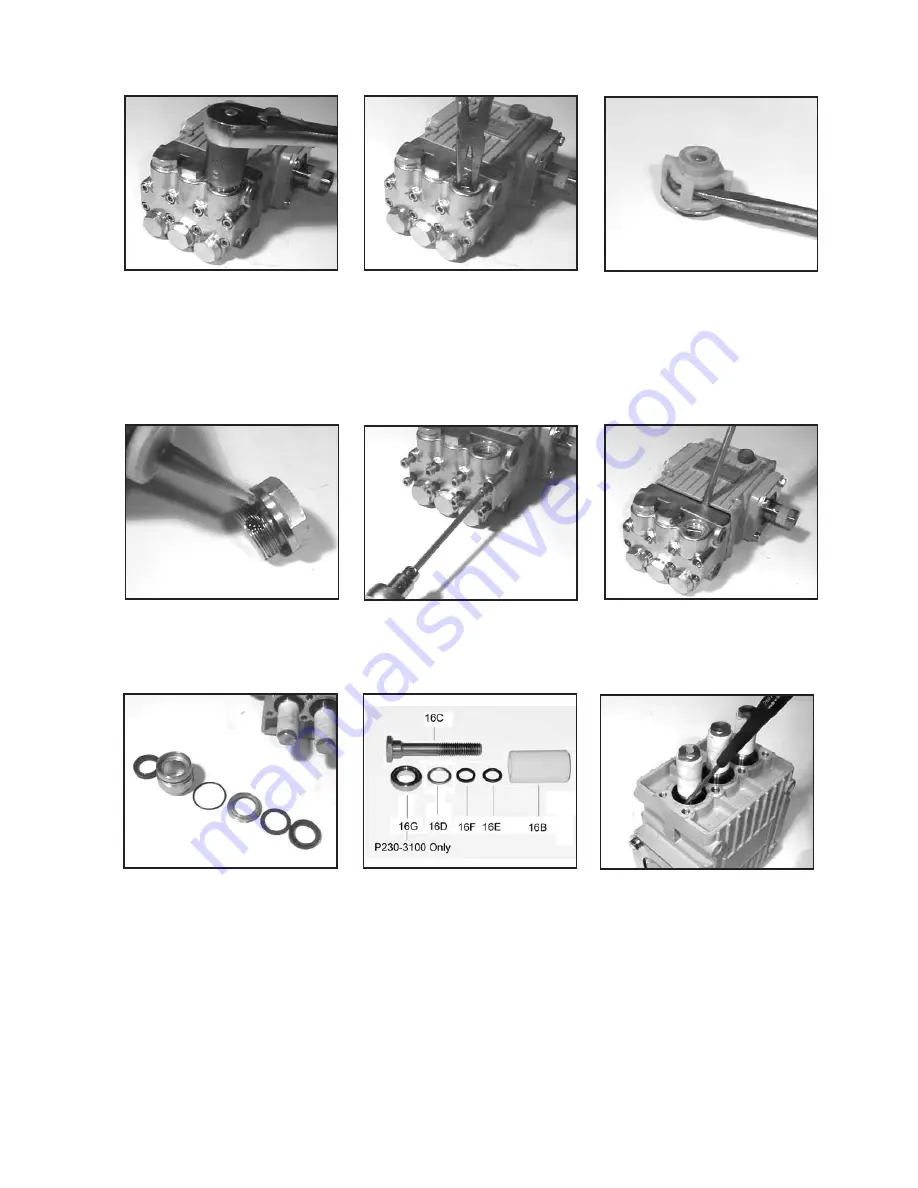

8.Check surfaces of plunger pipe

(16B). A damaged surface will cause

accelerated wear on the seals. De

-

posits of any kind must be carefully

removed from the plunger surface. A

damaged plunger must be replaced!

When replacing the crush washer

(item 16D), make sure the rolled side

of the crush washer is placed on the

ceramic. Prior to installation, care-

fully crush the seal ring on a hand

press.

9. If the crankcase oil seals

(19) are to be replaced,

they can be removed by

prying loose with a flat

screwdriver. Take care not

to make contact with the

plunger.

4. Apply one drop of Loctite

243 to the valve plugs (32)

and tighten to 33 ft.-lbs.

5. Next, use a 5mm allen

wrench to remove the 8

socket head cap screws

(34).

6. Carefully slide the valve

casing (26) out over the

plungers.