E44.X.01.6C-04

Mounting- and Operating Manual GIR 300

page 24 of 34

- Use button 2 and button 3 to set the desired value for the switching-delay of output 1.

Hint: The selected value [0.01 ... 2.00] will be in seconds.

-

Press button 1 to validate the selection. The display shows “

1.dEL

“ again.

-

When pressing button 1 again, the device will display “

1.Err

“ (preferred state of output 1).

- Use button 2 and button 3 (middle or right button) to set the desired initial state in case of an

error

.

Display

Preferred state of the out-

put

Notes

off

Inactive in case of an error

(contact is open)

on

Active in case of an error

(contact ist closed)

-

Press button 1 to validate the selection. The display shows “

1.Err

“ again.

- In case you selected a 3-point-controller you have to make the following settings similar to

the settings you already made for output 1:

“

2.dEL

“ (delay of output 2) and

“

2.Err

“ (preferred state of output 2).

Depending on the selected output function you have to make the settings for switching and alarm points.

See description in chapter

Fehler! Verweisquelle konnte nicht gefunden werden.

„

Fehler! Verweisquel-

le konnte nicht gefunden werden.

“ for further information.

Hint:

The settings for the switching and alarm points can be made later in an extra menu (see chapter

Fehler! Verweisquelle konnte nicht gefunden werden.

)

7

Switching points and alarm-boundaries

Note:

All relevant switching and alarm points can be set at this menu.

(Preferred output position and delay of the output can only be set at configuration menu)

Depending on the selected output function different parameters have to be adjusted.

The configuration menu automatically skips parameters not needed for the selected output

function.

Please note: The settings of the switching points and alarm-boundaries will automatically be reset

to factory default when any changes for the settings

„Func“, „Inp.1“ or „Unit“ had been

made!

General note:

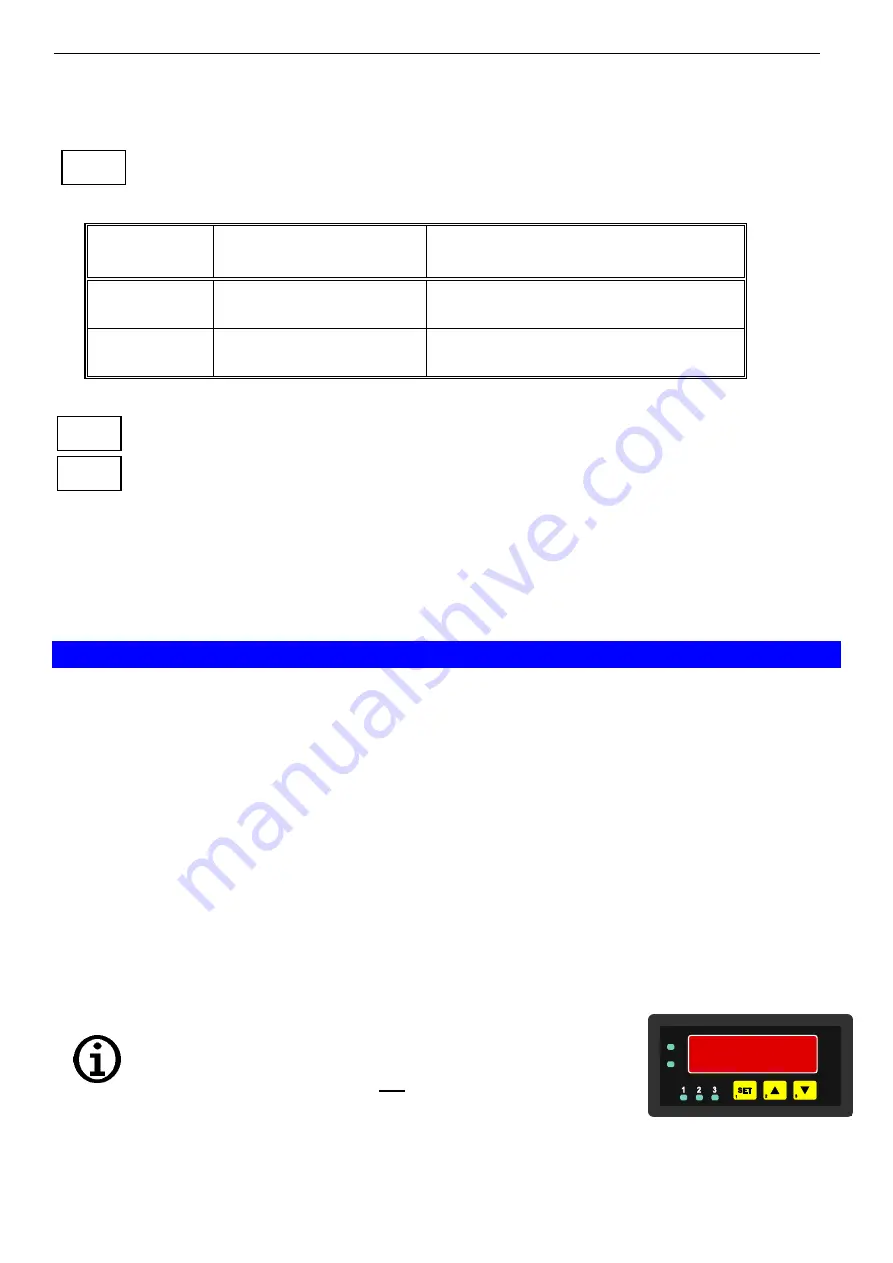

The state of the switching contacts is displayed with 2 LED´s. LED “1” displays the state of the contact

of relay 1 and LED “2” displays the state of contact of relay 2. (LED illuminate = contact is closed)

Hint:

The buttons 2 and 3 are featured with a ‘roll-function‘. When pressing the button once the value will be

raised (button 2) by one or lowered (button 3) by one.

When holding the button pressed for longer than 1 sec. the value starts counting up or down, the counting

speed will be raised after a short period of time.

The device also features a ‘overflow-function‘, when reaching the upper limit of the range, the device

switches to the lower limit, vice versa.

Please note:

When you are configuring the device and don’t press

any button for more than 60 sec. the configuration of

the device will be cancelled.

The changes you made will not be saved and will be

lost!

- When pressing button 1 for >2 sec. the menu to select the switching

points and alarm-boundaries will be called.

-

Depending on the configuration you have made in the „output“ menu

you will get different Display values.

Please follow the specific chapter for further information.

button 1 button 2 button 3

1.ERR

2.DEL

2.ERR