-Lock-out handle requiring key for access to work area.

-Digital pressure readout with low pressure alarm for work area.

-Inward/Outward face velocity is 95-100 linear feet per minute at gloveport opening, to

protect operator/product during massive breach of containment.

-Glove changes can be made without breaking containment.

-Locking casters are standard, seismic anchors are available.

Ergonomics-

-Hydraulic assist height adjusting stand offers a full 10” range variance allowing operators to

sit or stand comfortably for extended time periods.

-Stainless steel sliding tray inside the airlock pulls into the work area eliminating reaching

strains.

-Two part sleeve/glove system allows the use of most types and sizes of commercially

available gloves for better dexterity and tactility.

-Extra large oval gloveports are placed with bottoms together to provide an

athropometrically correct configuration that accommodates a wide range of body types and

increases range of movement.

-Gloveports have a 3” arm rest to reduce operator fatigue.

-Large viewing panel is at an angle to reduce glare and operator strain.

-Integrated foot rest.

Configuration Options-

-Overall work area pressure can be either positive or negative and can be altered in-place by

a certifier.

-Antechamber can be left or right handed or can be installed on both sides.

-Waste and sharps removal tubes can be left or right handed or can be installed on both

sides.

-Three available exhaust options that can be factory set or changed by a certifier in-place.

Filtration-

-Full framed standard size minipleat HEPAs filter 100% of inlet and exhaust air from both

the work area and the antechamber to provide a fully contained environment.

-HEPA filters are full coverage and front loading for easy replacement by a certifier.

-A Prefilter extends the life of the work area supply HEPA filter and can be replaced without

tools.

Electrical-

-High capacity motor/blower systems with speed control to extend HEPA filters life.

-Ten foot hospital grade power cord with molded grounded plug.

-Sealed outlet in work area.

-Separate lighted power ON/OFF indicator switches for blower and lighting.

-High efficiency, standard sized fluorescent lights are externally mounted to minimize heat

build-up.

-Voltage = 115 Volt, 60 Hz (220/50-60 Hz also available).

-Amperage Rating = 15, Running Amperage = 6

Exhaust-

-Clean air plenum is external to the work area.

-Constructed to allow for optional outside venting of exhaust air.

53

Summary of Contents for LFGI-3USP

Page 1: ...Laminar Flow LFGI CAI or CACI User Manual ...

Page 33: ...33 ...

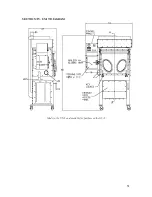

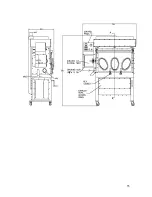

Page 51: ...SECTION IV UNIT DIAGRAM Made in the USA and available for purchase on the GSA 51 ...

Page 55: ...55 ...

Page 59: ...59 ...

Page 63: ...Fig 2 Air recycle plenum connection tip removed 63 ...

Page 85: ... 863 248 2800 www sensocon com 20 Installation and Operation Manual Series A3 A4 ...