Part No. 75861

Genie Z-60/34

4 - 45

November 2003

Section 4 • Repair Procedures

REV A

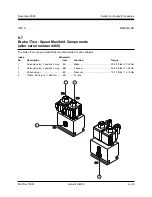

8-4

Valve Adjustments -

Function Manifold

How to Adjust the System

Relief Valve

Perform this procedure with the

boom in the stowed position.

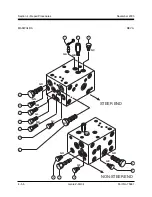

1 Connect a 0 to 5000 psi / 0 to 345 bar pressure

gauge to the test port (item Z) on the function

manifold.

2 Start the engine from the ground controls.

3 Hold the function enable switch to the high rpm

position and activate and hold the retract switch

with the boom fully retracted.

4 Observe the pressure reading on the pressure

gauge. Refer to Section 2, Specifications.

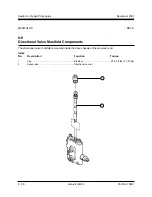

5 Turn the engine off. Use a wrench to hold the

relief valve and remove the cap (item T).

6 Adjust the internal hex socket. Turn it clockwise

to increase the pressure or counterclockwise to

decrease the pressure. Install the relief valve

cap.

Tip-over hazard. Do not adjust

the relief valve higher than

specified.

7 Repeat steps 2 through 5 and recheck relief

valve pressure.

8 Remove the pressure gauge.

How to Adjust the Primary Boom

Down Relief Valve

Perform this procedure with the

boom in the stowed position.

1 Connect a 0 to 5000 psi / 0 to 345 bar pressure

gauge to the test port (item Z) on the function

manifold.

2 Start the engine from the ground controls.

3 Hold the function enable switch to the high rpm

position and activate and hold the primary

boom down switch with the primary boom fully

lowered.

4 Observe the pressure reading on the pressure

gauge. Refer to Section 2, Specifications.

5 Turn the engine off. Use a wrench to hold the

relief valve and remove the cap (item AE).

6 Adjust the internal hex socket. Turn it clockwise

to increase the pressure or counterclockwise to

decrease the pressure. Install the relief valve

cap.

Tip-over hazard. Do not adjust

the relief valve higher than

specified.

7 Repeat steps 2 through 5 and recheck relief

valve pressure.

8 Remove the pressure gauge.

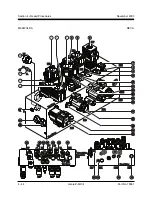

MANIFOLDS

Summary of Contents for Z-60/34

Page 12: ...Genie Z 60 34 Part No 75861 November 2003 This page intentionally left blank ...

Page 157: ......

Page 160: ...Electrical Schematic Deutz F4L 1011F Models November 2003 Section 6 Schematics ...

Page 162: ...Ground Control Box Wiring Diagram Deutz F4L 1011F Models November 2003 Section 6 Schematics ...

Page 164: ...Platform Control Box Wiring Diagram Deutz F4L 1011F Models November 2003 Section 6 Schematics ...

Page 165: ......

Page 168: ...Electrical Schematic Ford LRG 425 EFI Models November 2003 Section 6 Schematics ...

Page 170: ...Ground Control Box Wiring Diagram Ford LRG 425 EFI Models November 2003 Section 6 Schematics ...

Page 173: ...November2003 Section 6 Schematics PartNo 75861 GenieZ 60 34 6 11 ...

Page 176: ...Hydraulic Schematic 2WD Models before serial number 4461 November 2003 Section 6 Schematics ...

Page 178: ...Hydraulic Schematic 4WD Models before serial number 4461 November 2003 Section 6 Schematics ...

Page 180: ...Hydraulic Schematic 2WD Models after serial number 4460 November 2003 Section 6 Schematics ...

Page 182: ...Hydraulic Schematic 4WD Models after serial number 4460 November 2003 Section 6 Schematics ...