7

ASSEMBLY INSTRUCTIONS

•

SERIOUS PERSONAL INJURY COULD OCCUR IF YOU CONNECT

THE MACHINE TO THE POWER SOURCE BEFORE YOUR HAVE

COMPLETED THE SET UP PROCESS. DO NOT HOOK-UP THE MACHINE

TO A POWER SOURCE UNTIL INSTRUCTED TO DO SO.

• BE SURE TO READ AND UNDERSTAND THIS ENTIRE MANUAL. • USE

CAUTION AND WEAR GLOVES WHEN HANDLING METAL PARTS SUCH

AS THE BELT CLAMPS, WHICH CAN CUT IF HANDLED CARELESSLY.

• THE SOUND LEVEL OF THIS MACHINE IS RATED AT APPROXIMATELY

80-85 DB DURING OPERATION. MAKE SURE THAT ADEQUATE

HEARING PROTECTION IS USED AND THAT THE OVERALL SOUND

LEVEL WITHIN THE WORKING ENVIRONMENT IS TAKEN INTO

CONSIDERATION.

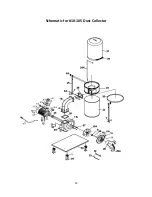

1.

Attach the 4 casters to the underside of the base

using 4 hex flange head bolts per caster, then

tighten the bolts using the supplied 8-10 mm

combination wrench. (Fig.1)

2.

NOTE

:

Help with lifting will be needed at this

time. The fan/ motor assembly is heavy - do not

overexert.

Turn the base back over (right side

up) and place the fan/motor assembly on the

plate. Line up the mounting holes and attach the

assembly to the base using 4 hex head bolts, 2 on

each side. (Fig.2)

3.

Place rubber gasket on top of motor housing

aligning holes in gasket with holes in motor

assembly. (Fig 3)

4.

Place the connector on the gasket and secure in

place using 8 bolts, in pre tapped holes. Tighten

bolts. (Fig. 4)

NOTE: Do not overtighten the bolts or the

threaded holes in the base will strip and/or the

gasket will squeeze out and the outlet will

crack.

Fig.1

Fig. 2

Fig. 3

Fig. 4