12

3.1

CHECKING THE ENGINE OIL

LEVEL

For oil capacities and requirements, see the “Engine Oil

Requirements” section. Check the engine crankcase oil level at

least every eight hours of operation, or before it is used. To check

the engine oil level, proceed as follows (see Figure 3.1):

1. Be sure the generator is as level as possible.

2. Remove the dipstick and wipe it dry with a clean, lint-free

cloth.

3. Install and tighten the dipstick cap; then, remove it again. The

oil level should be at the dipstick “Full” mark.

4. If necessary, remove the oil fill cap on the rocker cover and

slowly add oil until it reaches the dipstick “Full” mark. DO NOT

FILL ABOVE THE “FULL” MARK.

n

Never operate the engine with the oil level

below the “Add” mark on the dipstick. Doing

this could damage the engine.

5. Install and tighten the oil fill cap and the dipstick before oper-

ating the engine.

3.2

CHANGING THE ENGINE OIL

AND/OR OIL FILTER

n

Hot oil may cause burns. Allow engine to cool

before draining oil. Avoid prolonged or repeat-

ed skin exposure with used oil. Thoroughly

wash exposed areas with soap.

Change the

•

engine oil

after the first 25 hours of operation.

Thereafter, change the oil every 100 operating hours. Change

the oil more frequently if operating consistently under heavy

load or at high ambient temperatures.

Change the engine

•

oil filter

after the first 25 hours of operation,

and every 100 operating hours thereafter.

To change the oil and/or oil filter, proceed as follows:

1. Run the engine until it is thoroughly warmed up (at least five

minutes) then shut OFF the engine.

2. With the engine still warm from running, remove the oil drain

plug (Figure 3.1). Drain the oil into a suitable container.

3. After the oil has drained, replace the oil drain plug. (If only

changing the oil, go to step 7.)

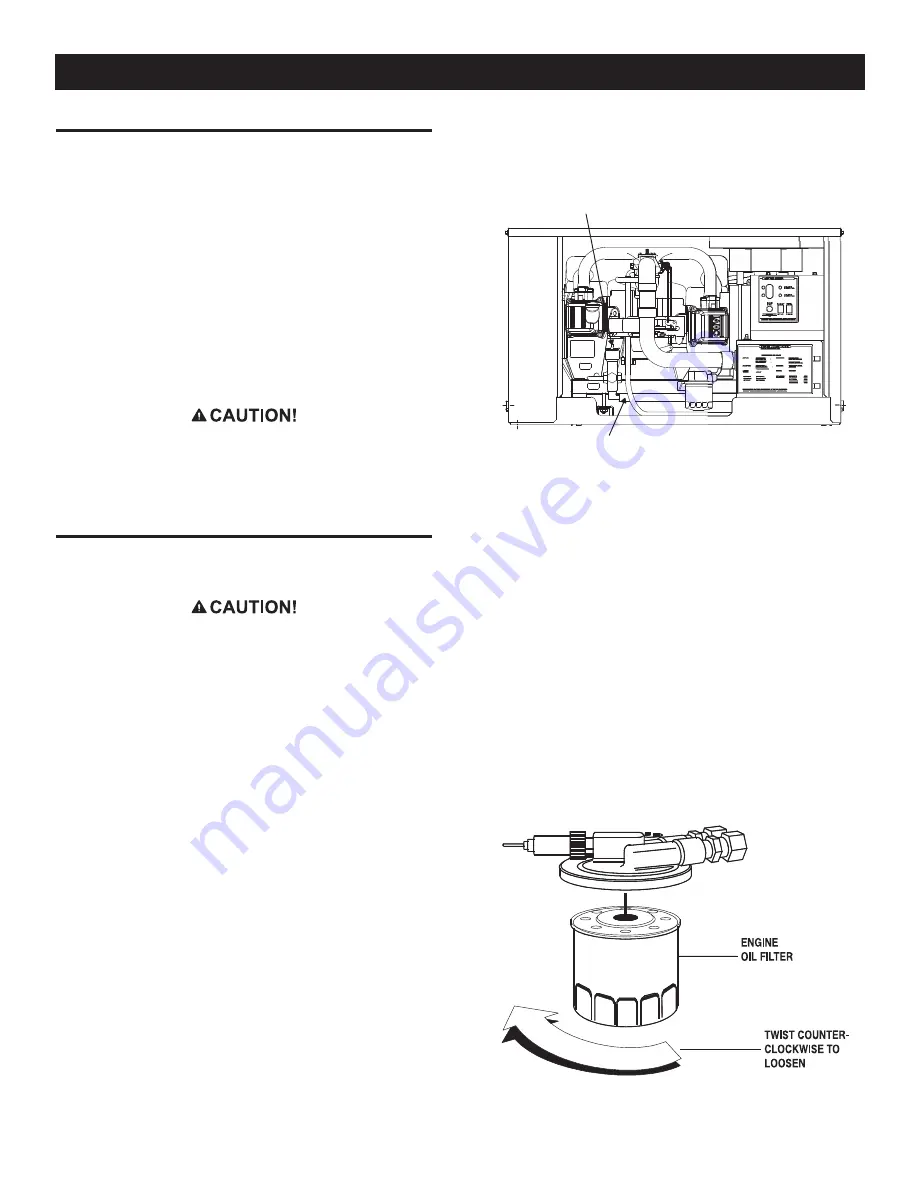

4. With the oil drained, remove the old oil filter by turning it coun-

terclockwise (Figure 3.2).

5. Apply a light coating of clean engine oil to the gasket of the

new filter.

6. Screw the new filter on by hand until its gasket lightly contacts

the oil filter adapter. Then, tighten the filter an additional 3/4 to

one turn.

3. After the oil has drained, replace the oil drain plug. (If only

changing the oil, go to step 7.)

4. With the oil drained, remove the old oil filter by turning it coun-

terclockwise (Figure 3.2).

Figure 3.1 — Oil Dipstick/Fill Tube and

Location of Oil Drain Plug

Oil Dipstick

Oil Drain Hose

5. Apply a light coating of clean engine oil to the gasket of the

new filter.

6. Screw the new filter on by hand until its gasket lightly contacts

the oil filter adapter. Then, tighten the filter an additional 3/4 to

one turn.

7. Remove the dipstick and fill crankcase with the proper

type and amount of recommended oil (see "Engine Oil

Requirements"). The engine crankcase can hold about 1.8

liters or 1.9 quarts with oil filter change. DO NOT FILL ABOVE

THE “FULL” MARK.

8. Install and tighten the dipstick before operating the engine.

9. Start the engine and check for leaks.

10. Dispose of used oil at a proper collection center.

NOTE:

Check the oil level and fill to the “FULL” mark after checking for

leaks. The filter will retain some oil.

Figure 3.2 — Engine Oil Filter

Maintenance

Summary of Contents for 004703-1

Page 19: ...17 Notes...

Page 20: ...18 Notes...

Page 25: ...23 Figure 1 2 Major Features and Dimensions Drawing No 0E1058 H General Information...

Page 30: ...28 Figure 2 8 Compartment Floor Cutout Drawing 0G3529 A Installation...

Page 42: ...40 Electrical Data Electrical Schematic V twin Drawing No 0E1057 F...

Page 43: ...41 Electrical Schematic V twin Drawing No 0E1057 F Electrical Data...

Page 44: ...42 Exploded Views Parts Lists Base Pulley Drawing No 0E1323 H...

Page 46: ...44 Exploded Views Parts Lists Enclosure Drawing No 0G7865 C...

Page 48: ...46 Exploded Views Parts Lists Engine Accessories Drawing No 0G7866 E...

Page 50: ...48 Exploded Views Parts Lists Control Panel Drawing No 0E1013 B...

Page 52: ...50 Exploded Views Parts Lists 760 V twin Engine Drawing No 0F1997 C...