MU-A-RectiRail DL2-rev01a-Gb

41

/ 44

7.8.3

Reading and comparing measurements

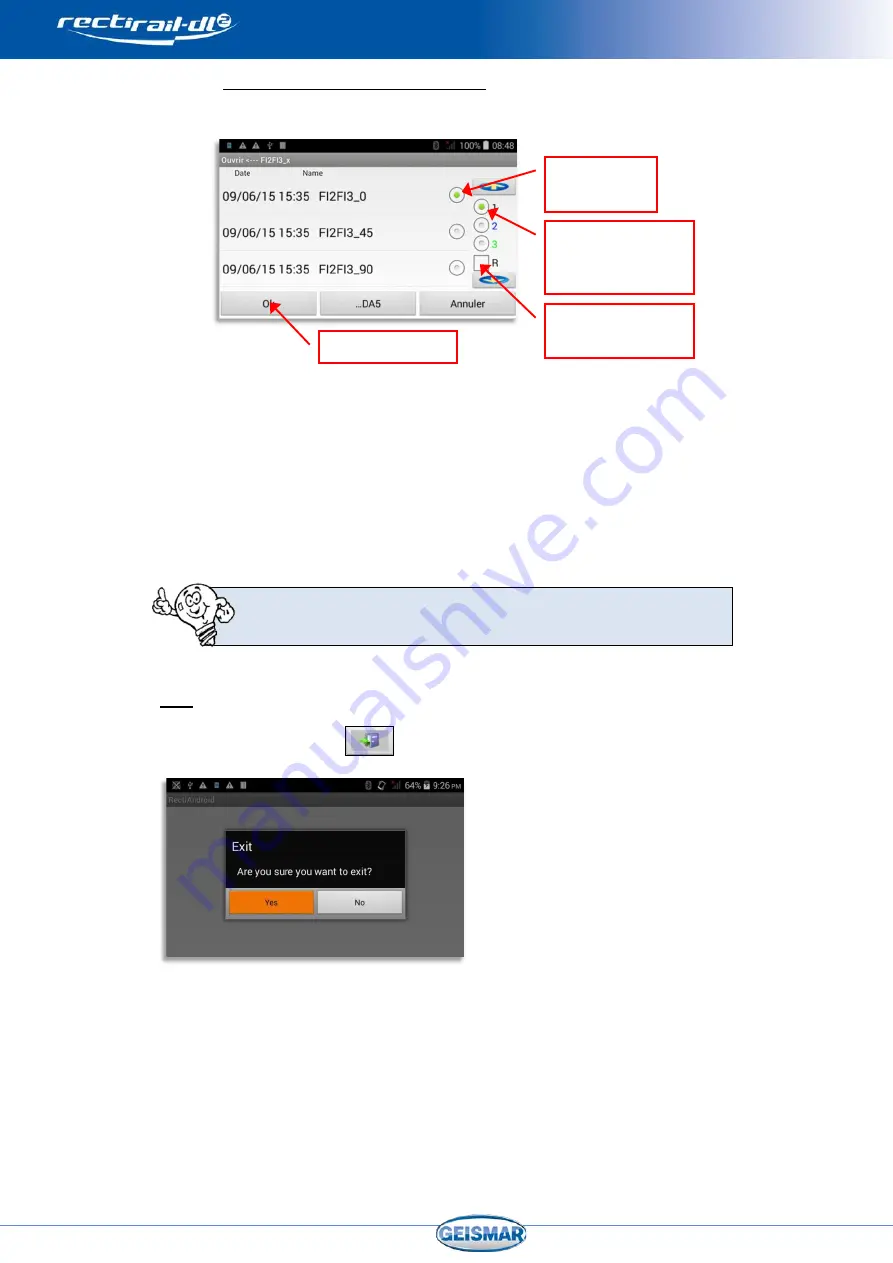

When reading a measurement, the following screen is displayed:

Once the choice has been validated by OK, you can request reading of a

second measurement. To do this, select “open”, then

- Highlight the required curve

- Select a

different

position

Validate by OK: both curves are now displayed. Proceed likewise to visualise a

3rd curve.

If ticked, the “R” box lets you reset the display (deletion of the

curves on the screen)

8

Exit

Click on the “Exit” button

to exit the software.

Confirmation is required to exit the application.

Exiting the application will automatically switch off the RectiRail.

Select the

measurement

Select the required

position for this

measurement

Validate by OK

Delete the other

measurements