– 62 –

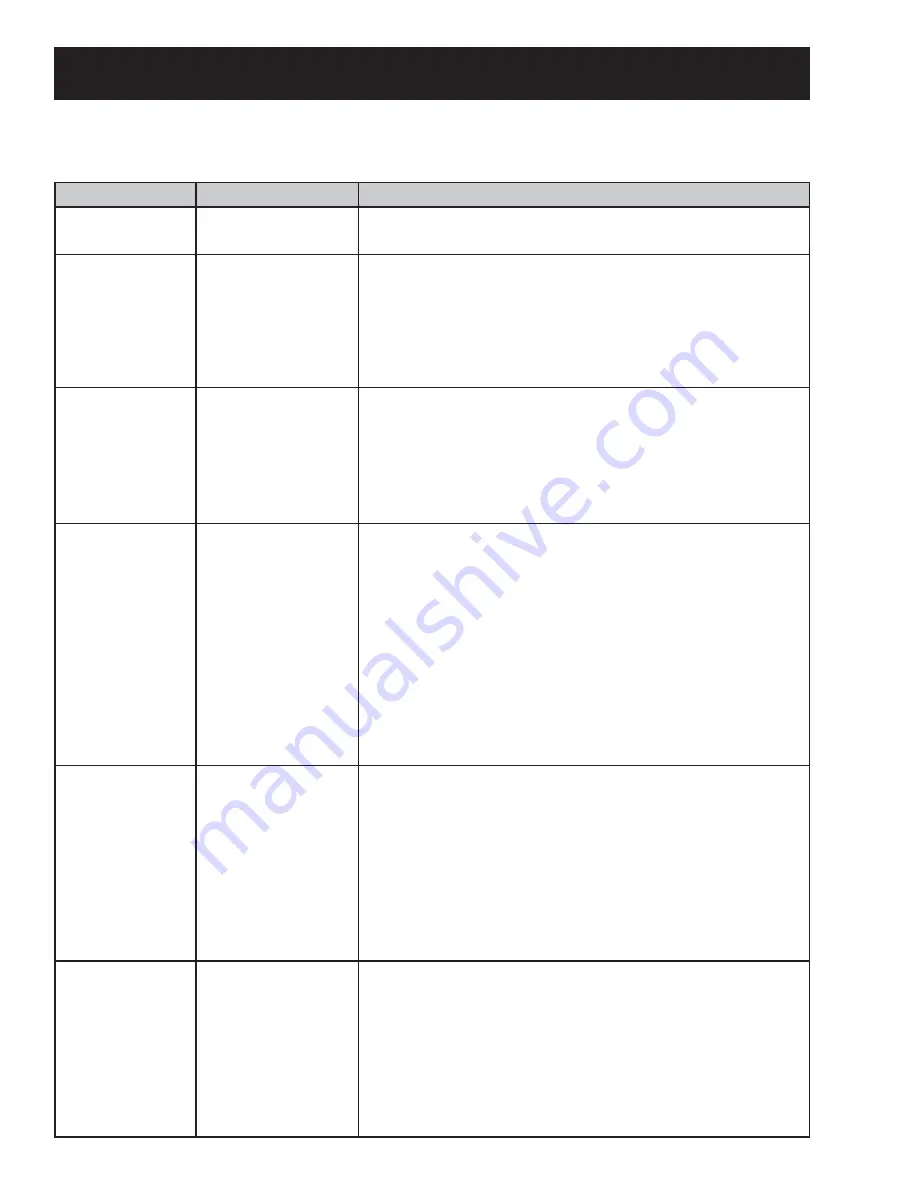

Error Codes

(Continued Next Page)

Error Code

Description

Action

E1 UI EEPROM

E2 Power EEPROM

Internal problem with

UI or MC board

• Replace board as necessary.

E4 Thermistor

Short

E5 Thermistor

Open

Water Temperature

Sensor Problem

• Check integrity of wiring and connections between main

control and Thermistor Assembly.

• Using ohmmeter, measure Thermistor resistance. If outside

expected range, replace Thermistor Assembly.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace the main control.

E6 Pressure

Switch

Water Level Sensor

Problem

• Check integrity of wiring and connections between main

control and Water Level Sensor.

• Check integrity of Water Level Sensor; replace if necessary.

• Check drain system.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace the main control.

E7 Slow Fill

Fill Problem

• Ensure manual water valves are fully open.

• Check if water strainers on solenoid valve assembly are

clogged.

• Check for obstructions inside inlet water hoses.

• Ensure solenoid valves do not leak when the valves are de-

energized and the washer is powered down.

• Measure coil resistance for both valves. If outside range

(1000–1250 ohms at room temp), replace solenoid valve

assembly.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace solenoid valve assembly.

E8 Drain System

Drain Problem

• Ensure pump strainer is clean and free of debris.

• Check for obstruction inside the drain hose.

• Check pump impeller blades and bearing; if evidence of

blade damage or seized bearings are present, replace the

pump.

• Check the electrical connections at the pump motor and

harness.

• Measure pump motor resistance. If outside range (9–14

ohms at room temp), replace the pump.

E9 Dispenser

Motor

Dispenser Problem

• Check for obstruction in dispenser mechanism and

linkages.

• Check the electrical connections at the motor feedback

switch and in the harness.

• Check the electrical connections of water valves in the

harness.

IF ABOVE STEPS DO NOT CLEAR THE PROBLEM:

• Replace dispenser motor assembly.

Note:

It’s important to note error codes should only be used to help identify components which require

testing.

Never replace a part based solely on an error code.

The control can generate a false error if the

right conditions exist. Use the code only as a reference and always check the component before replacing.

Summary of Contents for PFWS4400L0

Page 9: ... 9 Continued Next Page ...

Page 11: ... 11 Continued Next Page ...

Page 13: ... 13 Continued Next Page ...

Page 14: ... 14 Continued Next Page ...

Page 19: ... 19 ...

Page 22: ... 22 Dispenser Drawer Tub Drive Pulley Belt Motor Rear View Front View Con t ...

Page 65: ... 65 Schematics Model 4600 with Steam ...

Page 66: ... 66 Model 4400 without Steam ...