GEH-5304A

31

An extreme overload or electrical failure may result in heating or arcing, which

can cause the insulation to give off noxious fumes. All power should be re-

moved from the motor circuit as a precaution, even though the circuit has

overload protection. Personnel should not approach the motor until adequate

ventilation of the area has purged the air of fumes. When covers of a totally

enclosed

motor are removed after a failure, care should be observed to avoid breathing fumes from inside

the motor. Preferably, time should be allowed for the motor to cool before attempting any ex-

amination or repair.

Water should not be applied to any electrically energized equipment because

electric shock could result in serious or fatal injury. In case of fire, disconnect

all power and use a carbon dioxide extinguisher to quench the flame.

Before operating any motor after a suspected failure, it should be inspected for

damage. Remove covers and make visual inspections of the brushes, commutator, connections

and windings. Electrical tests of each winding to check for open or short circuit or grounds

should be made. Any arc damage should be cleaned up and repaired as necessary. Brushes

may need reseating before operation.

VI.

RENEWAL PARTS

Using genuine GE renewal parts assures continued high performance and the full benefits of the long operating life

designed into your GE motor.

Downtime can be minimized by having a protective stock of parts available for replacement. (Refer to Table 14.)

The permanently attached nameplate on your GE motor displays the model and serial number, providing all the

information needed for ordering. Parts are available directly from authorized GE Industrial Systems parts dis-

tributors. Direct electronic access to the factory database of motor information and warehouse inventories enables

distributors to quickly identify part numbers, delivery times and order status.

A.

Storage of Renewal Parts

Store supply parts in a clean, dry, ventilated place, protected from rodents and termites, to prevent damage or

loss. Slush all finished iron or steel surfaces with heavy oil or compound to protect them from corrosion.

The parts should be inspected occasionally to ensure their continuous usability.

Summary of Contents for GEH-5304A

Page 26: ...GEH 5304A 26 ues ...

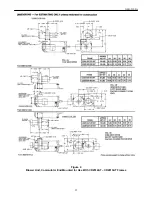

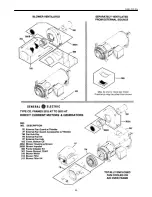

Page 34: ...GEH 5304A 34 Figure 3 Application Information for CD2512AT CD2813AT Frames ...

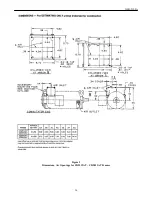

Page 36: ...GEH 5304A 36 Figure 5 Dimensions Air Openings for CD2512AT CD2813AT Frames ...

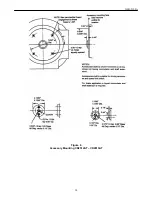

Page 38: ...GEH 5304A 38 Figure 6 Accessory Mounting CD2512AT CD2813AT ...

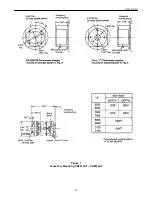

Page 39: ...GEH 5304A 39 Figure 7 Accessory Mounting CD2512AT CD2813AT ...

Page 40: ...GEH 5304A 40 ...

Page 43: ...GEH 5304A 43 Detach and fax or mail to the address noted above ...