GEH-5304A

30

FREON TF is a chlorofluorocarbon. Chlorofluorocarbons have been identified

as upper atmosphere ozone depletors. The use of Freon in industry is expected

to be greatly reduced in the future. The availability of Freon may be limited, and

its use could be prohibited by regulations.

Carbon brush performance may be ruined by absorbed solvents. Remove

brushes prior to solvent wiping.

N.

Drying of Windings

Drying of machines is most effectively done by application of heat. The windings and insulation should be

heated so that their temperature does not exceed 225

°

F (125

°

C) at any location. (Do not make local hot

spots.) The machine’s own frame and the addition of some covers usually will make an effective enclosure

to contain the heat, if an oven cannot be used. Some flow of air is desirable to allow moisture to be carried

away. Methods of generating heat include blowing hot air through the machine, heating with heat lamps,

passing current through the main field coil windings, etc.

If temperatures as high as 225

°

F (125

°

C) can be attained, they should be limited to six or eight hours dura-

tion. Lower temperatures will cause correspondingly longer drying times.

Drying out can be ended when the insulation resistance to ground (corrected to 40

°

C) is restored to a satis-

factory value as described in the Insulation Resistance section. If these values do not reach a proper level,

then a thorough cleaning or complete reconditioning may be necessary.

O.

Service Shop Cleaning

When the cleaning or drying methods described in preceding paragraphs do not result in restoration of ac-

ceptable insulation resistance and/or when machines are extremely dirty or contaminated, it is recommended

that the reconditioning services of a GE Service Shop be obtained. Service shops are knowledgeable and

equipped for more sophisticated restoration methods, such as hot water detergent wash, solvent and abrasive

cleaning, revarnishing and rewinding, if necessary.

P.

Repair

Repairs should be made only by qualified personnel using the materials and processes for which the motor

was designed. To protect the warranty during the warranty period, all repairs must be made in a GE Service

Shop or approved repair facility. Many repairs can be easily performed with only assembly operations, if GE

replacement parts are available. If major repairs are undertaken (such as rewinding an armature), proper fa-

cilities should be used and suitable precautions observed.

When burning off old insulation materials or when welding near insulation

during rewinding, adequate ventilation must be provided to avoid exposing

personnel to noxious fumes. Combustion of exhaust fumes must be complete

and adequately vented to the outside atmosphere.

Exposure of personnel to airborne inorganic fibers must be avoided by ade-

quate ventilation or by wetting the remaining insulation components following

the burning off of the organic materials.

Summary of Contents for GEH-5304A

Page 26: ...GEH 5304A 26 ues ...

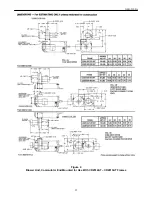

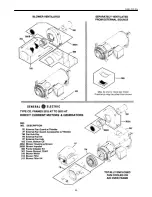

Page 34: ...GEH 5304A 34 Figure 3 Application Information for CD2512AT CD2813AT Frames ...

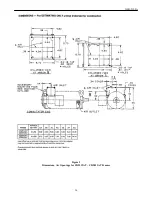

Page 36: ...GEH 5304A 36 Figure 5 Dimensions Air Openings for CD2512AT CD2813AT Frames ...

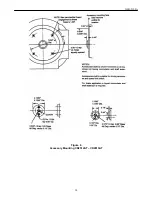

Page 38: ...GEH 5304A 38 Figure 6 Accessory Mounting CD2512AT CD2813AT ...

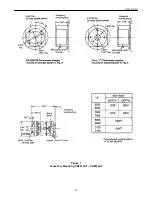

Page 39: ...GEH 5304A 39 Figure 7 Accessory Mounting CD2512AT CD2813AT ...

Page 40: ...GEH 5304A 40 ...

Page 43: ...GEH 5304A 43 Detach and fax or mail to the address noted above ...