GEH-5304A

29

Dirt can be removed from stationary parts of the machine by either compressed air or a vacuum nozzle or a

combination of both. Air should be directed between the stator coils, into the pocket corners of bearing

brackets, around the cables and onto the brush rigging. Special care should be taken to keep the commutator

clean. The commutator should be wiped with a clean lint-free cloth after blowing out.

Safety glasses and/or other protective equipment should be used to prevent

injury to eyes and respiratory organs.

High voltage electric shock can cause serious or fatal injury. Electrical circuits

must be de-energized prior to cleaning or other maintenance activities. Ground

electrical circuits prior to cleaning or maintenance to discharge capacitors.

Failure to observe these precautions may result in injury to personnel.

Liquid solvents should not be directly applied to the commutator, armature,

field coils or any electrical part of a DC machine. Liquid solvents carry con-

ducting contaminants (metal dust, carbon, etc.) deep into hidden areas to pro-

duce shorts and grounds, thus causing machine failure. Mechanical compo-

nents may be cleaned by a wiping rag barely moistened (not wet) with a solvent.

Solvents may be flammable and moderately toxic. The usual precautions for

handling chemicals of this type must be observed. These include:

1.

Avoid excessive contact with skin.

2.

Use in well ventilated areas.

3.

Take necessary precautions to prevent fire or explosion hazards.

1.

Oily Dirt

The presence of oil makes thorough, effective cleaning of machines in service virtually impossible and

service shop conditioning is recommended. Oil on a surface forms a “fly paper effect”, which attracts

and holds firmly any entrained dust. Neither suction nor compressed air is effective. Consequently,

only accessible areas may be cleaned. First, remove as much of the dirt as possible by scraping or

brushing the dirty surfaces. Then, wipe away as much dirt as possible with dry rags. For surfaces not

readily accessible, a rag on a hook wire can be used to clean dirt out of holes and crevices. Rags

should be changed frequently for clean ones so that contamination picked up from one area is not car-

ried to other less dirty areas.

While FREON TF

is considered to be nonflammable and has a relatively low

order of toxicity, it should be used only in well ventilated areas that are free

from open flames. Avoid prolonged exposure to vapors. Failure to observe

these precautions may result in injury to personnel.

FREON TF is the only recommended solvent for cleaning because it is nonflammable, has good sol-

vency for grease and oil, is considered safe with most varnishes and insulations and has a low order of

toxicity. Stoddard solvent has good solvency, but is flammable and moderately toxic. Before using

any solvent, consult the Material Safety Data Sheet. Steam cleaning is not recommended because, as

with liquid solvents, conducting contaminants may be carried deep into inaccessible areas resulting in

shorts and grounds.

Summary of Contents for GEH-5304A

Page 26: ...GEH 5304A 26 ues ...

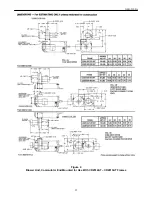

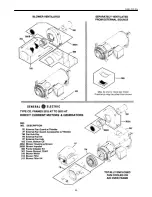

Page 34: ...GEH 5304A 34 Figure 3 Application Information for CD2512AT CD2813AT Frames ...

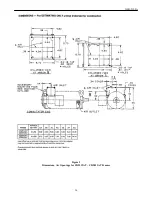

Page 36: ...GEH 5304A 36 Figure 5 Dimensions Air Openings for CD2512AT CD2813AT Frames ...

Page 38: ...GEH 5304A 38 Figure 6 Accessory Mounting CD2512AT CD2813AT ...

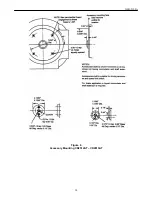

Page 39: ...GEH 5304A 39 Figure 7 Accessory Mounting CD2512AT CD2813AT ...

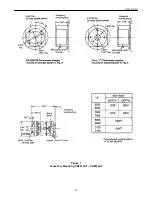

Page 40: ...GEH 5304A 40 ...

Page 43: ...GEH 5304A 43 Detach and fax or mail to the address noted above ...