Chapter 4. Printing Data

68

DigitalFlow™ GF868 Programming Manual (2-Channel)

4.5 Stop Printing

Use the

STOP

submenu to terminate the printing of live, logged or site data. To stop any active printing activity, see

Figure 16 on page 92 and complete the following steps:

IMPORTANT:

Make sure that a printer has been properly set up before proceeding with this section.

1.

To access the

Print Menu

, press the

[PRNT]

key.

Note:

The

Print Menu

is not protected by the security feature and a password is never required to access this menu.

2.

Press

[F4]

=

STOP

.

3.

Press

[F1]

to continue printing or press

[F2]

to

Stop

the currently active printing job.

Note:

After the STOP command has been issued, the printer will complete the printing of any data already in the

printer buffer. Either wait for the printer to finish or turn the printer off to empty the buffer immediately.

The Model GF868 returns to the standard data display screen and normal measurement taking.

4.6 Setting Up a Printer

Use the

PRNTR

submenu to specify the type of printer connected to the Model GF868. To set up a printer, refer to

Figure 16 on page 92 and complete the following steps:

IMPORTANT:

A printer must be properly set up before proceeding to any of the other sections in this chapter

1.

To access the

Print Menu

, press the

[PRNT]

key.

Note:

The

Print Menu

is not protected by the security feature and a password is never required to access this menu.

2.

Press the [

or [

key to display the option bar shown, and then press

[F1]

to select the

PRNTR

submenu.

3.

Use the [

, [

and

[F1]-[F4]

keys to select the desired

Printer Type

. See Table 20 for a complete list of the

available options.

Note:

For compatibility with the Model GF868, the printer must have an RS232 serial interface. To use a printer with

a parallel interface, a serial-to-parallel adapter must be used.

After the desired printer type has been selected, the meter returns to the standard data display screen and normal

measurement taking.

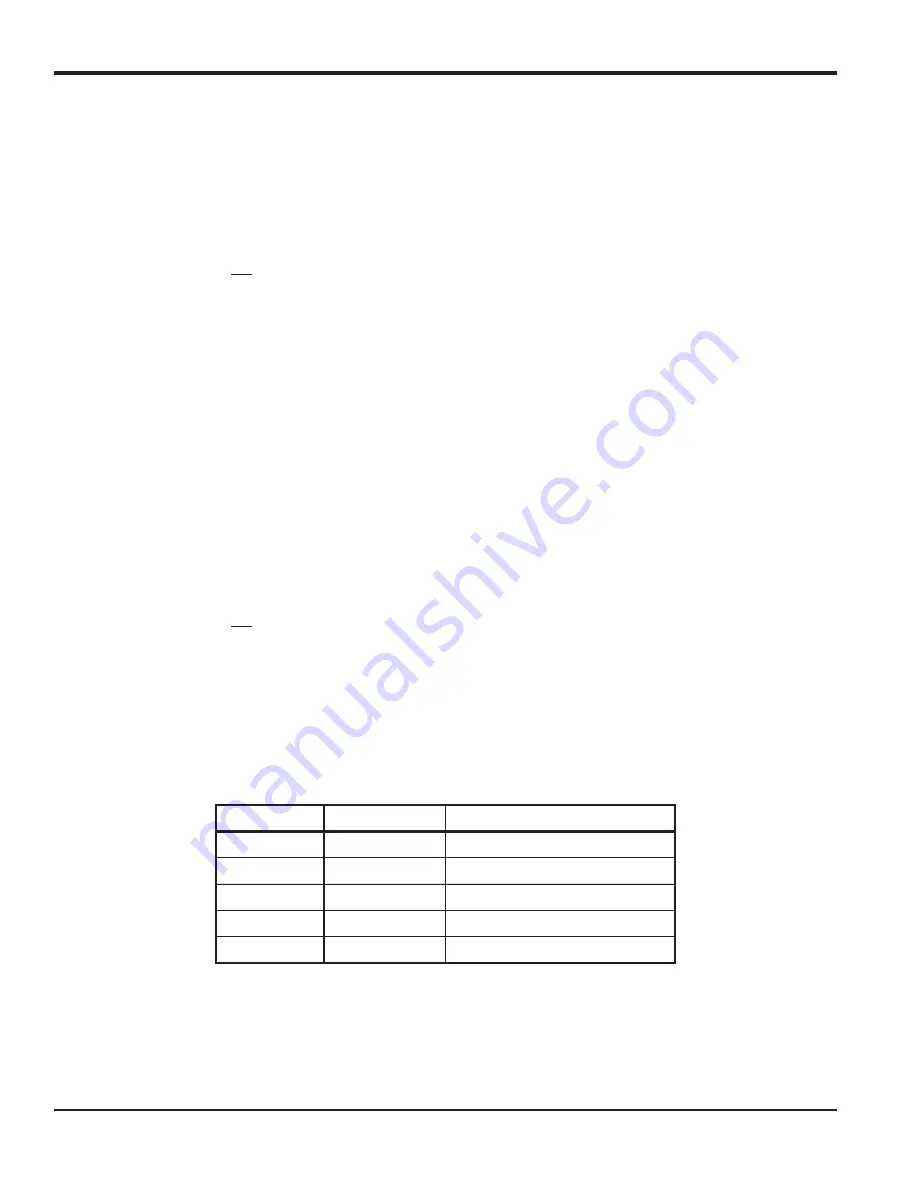

Table 20: Available Printer Options

Key(s)

Printer Type

Description

[F1]

DP411

Seiko Model DPU-411 Type II

[F2]

XTECH

Extech Mini Serial Printer 42

[F3]

EPSON

Epson or Epson-compatible

[F4]

KODAK

Kodak Diconix 150 Plus

[

+ [F1]

SP401

Syntest SP-401

Summary of Contents for DigitalFlow GF868

Page 2: ......

Page 4: ...ii no content intended for this page ...

Page 95: ...DigitalFlow GF868 Programming Manual 2 Channel 85 Appendix A Menu Maps Appendix A Menu Maps ...

Page 96: ...86 DigitalFlow GF868 Programming Manual 2 Channel no content intended for this page ...

Page 104: ...Appendix A Menu Maps DigitalFlow GF868 Programming Manual 2 Channel 94 ...

Page 108: ...98 DigitalFlow GF868 Programming Manual 2 Channel no content intended for this page ...

Page 146: ...Warranty 136 DigitalFlow GF868 Programming Manual 2 Channel no content intended for this page ...

Page 150: ......

Page 151: ......