Power Circuit Breakers Types AK-2-15 and AK-2/3-25 GEI-50299

6. If

the breaker is manually operated, and has

no auxiliary switch, it is now free to be lifted

clear of the breaker.

If

it has an auxiliary

switch, this may be disconnected from the

mechanism as described under "Auxiliary

Switch - Replacement, elsewhere in these

instructions.

7. If

the breaker is electrically operated, it will

be necessary to disconnect the mechanism from

the solenoid armature.

In

order to do this,

raise the mechanism as far as the travel of the

armature will permit and remove the screw

which binds together the two extensions

of

the

armature. After this is removed, the armature

extensions must be spread apart to release

them from the link connecting with the mech

anism.

This can be done by threading a

#10-32

screw at least

1-3/4

inches long into

the top hole of the armature extension. This

hole is just above the one from which the

binding screw has been removed. As the end

of the screw butts against the far extension,

the two extensions will be spread open, re

leasing the mechanism

link

.

8.

The replacement mechanism may be installed

by reversing the order of procedure for dis

assembly. After reassembly, check the opera

tion of the breaker and, if necessary, adjust

the latch engagement.

REMOVAL OF FRONT ESCUTCHEON

OF MANUAL BREAKERS

1.

Remove set screw fastening the plastic handle

to steel operating shaft and remove the oper

ating

2.

Open and remove annealed (soft) retainer and

two flat washers from shaft.

3.

Remove four screws from flange of escutcheon

If

the breaker is a drawout type, two small

round head screws must also be removed from

the bottom edge of the escutcheon.

4.

Push steel operating shaft through escutcheon

bushing.

5.

Remove handle reset spring

(8)

Figure

6,

and

escutcheon is free of breaker.

6 .

Handle and escutcheon assembly can be as

sembled most easily by exactly reversing the

procedure for disassembly. In replacing the

escutcheon it may be necessary to use pliers

to pull the operating shaft fully into the

escutcheon in order to have space enough to

replace the flat washers and the soft retainer.

The latter may be closed on its groove in

the shaft by ordinary gas pliers. After re

placement,

check operation of breaker.

AUXILIARY SWITCH

The auxiliary switch is mounted on the left

side of the operating mechanism frame. Its opera

ting shaft is linked to the output crank

of

the breaker

mechanism.

Through a cam arrangement, the

operating shaft of the switch controls the open and

closed positions of the individual contact pairs.

Each stage of the switch, which is usually two-stage

or five-stage, contains one "a" and one

''b"

set

of contacts.

An

"a" pair of contacts is always in

the same position as the main breaker contacts .

That is, open when the breaker contacts are open,

and closed when the breaker contacts are closed.

Just the oposite is true of the "b" contacts. The

terminals of the switch are covered by a sheet of

insulating material held in place by two screws

fastened along its left edge. When this is removed,

the terminals are exposed. The upper pairs of

terminals are those which connect to "a" switches.

The lower terminals connect to

''b"

switches.

REPLACEMENT

1.

Remove auxiliary switch cover.

2.

Disconnect leads to switch terminals.

3.

Remove two screws which fasten switch to

side

of

mechanism frame.

4.

Remove switch by moving towards left.

5.

Before mounting replacement switch, turn the

crank end

of the switch operating shaft in

position to engage the hole in the link con

necting with with the breaker mechanism.

Be sure the bearing washer is in place between

the mechanism

link

and the switch operating

shaft.

6.

Complete mounting by following disassembly

steps in reverse order.

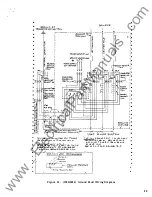

ELECTRICAL CONTROL COMPONENTS

These consist

of

the following:

1.

Closing solenoid

2. "X"

contactor (relay)

3 .

"Y"

permissive relay

4.

Cut-off switch

5.

Closing switch

6.

Shunt-trip device

The last two of these components may or

may not be present in the control arrangement.

15

www

. ElectricalPartManuals

. com