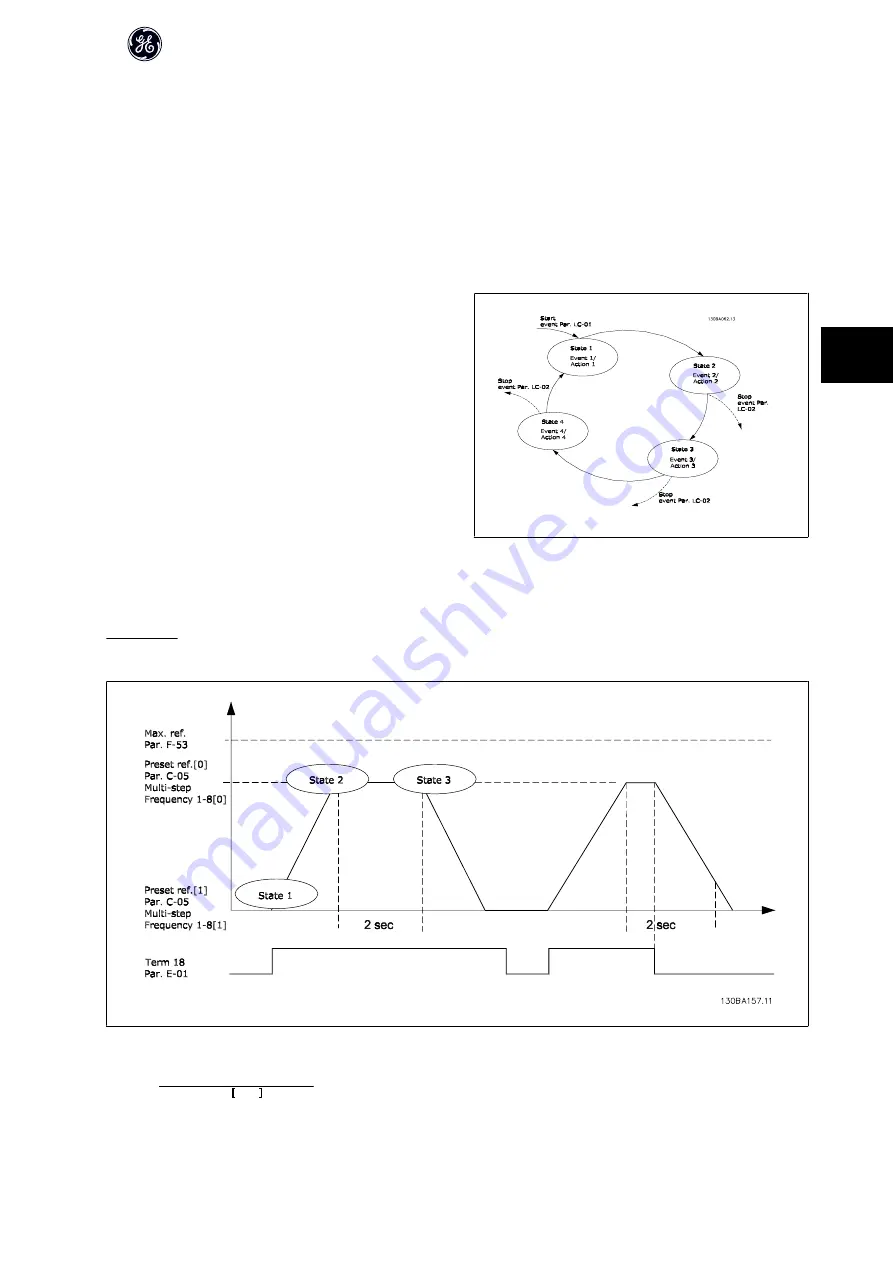

5.1.6 Logic Controller Programming

The Logic Controller (LC) is essentially a sequence of user defined actions (see par. LC-52

Logic Controller Action

) executed by the LC when the associated user

defined

event

(see par. LC-51

Logic Controller Event

) is evaluated as TRUE by the LC.

Events

and

actions

are each numbered and are linked in pairs called states. This means that when

event [1]

is fulfilled (attains the value TRUE),

action [1]

is executed.

After this, the conditions of

event [2]

will be evaluated and if evaluated TRUE,

action [2]

will be executed and so on. Events and actions are placed in array parameters.

Only one

event

will be evaluated at any time. If an

event

is evaluated as FALSE, nothing happens (in the LC) during the present scan interval and no other

events

will be evaluated. This means that when the LC starts, it evaluates

event [1]

(and only

event [1]

) each scan interval. Only when

event [1]

is evaluated TRUE, the LC

executes

action [1]

and starts evaluating

event [2]

.

It is possible to program from 0 to 20

events

and

actions

. When the last

event /

action

has been executed, the sequence starts over again from

event [1] /

action [1]

. The illustration shows an example with three

events / actions

:

5.1.7 LC Application Example

One sequence 1:

Start – accel – run at reference speed 2 sec – decel and hold shaft until stop.

Set the accel/decel times in par. F-07

Accel Time 1

and par. F-08

Decel Time 1

to the wanted times

tramp

=

tacc

×

nnorm

(

par

.

P

−

06)

ref

RPM

AF-600 FP Design Guide

97

5

Summary of Contents for AF-600 FP Series

Page 11: ...AF 600 FP Design Guide 10 2...

Page 45: ...AF 600 FP Design Guide 44 3...

Page 51: ...Do not combine low voltage parts and PELV systems AF 600 FP Design Guide 50 3...

Page 58: ...4 How to Install AF 600 FP Design Guide 57 4...

Page 95: ...AF 600 FP Design Guide 94 5...

Page 102: ...5 1 11 Fixed Variable Speed Pump Wiring Diagram AF 600 FP Design Guide 101 5...

Page 105: ...AF 600 FP Design Guide 104 6...