Ricoh StreamPunch Pro, Pro EX & MP Installation Manual

9

7. Final Steps

7.1 Printer & Finisher Firmware

Confirm that the printer and finisher have the latest firmware installed. Firmware is available for download

at

www.tscweb.net

(US) or

www.ricoh-support.com/techuser/

(EU) or can be obtained by contacting

Ricoh service.

Special custom engine firmware must be installed if installing the StreamPunch with the Martini-C4 (MP

6001/7001/8001/9001).

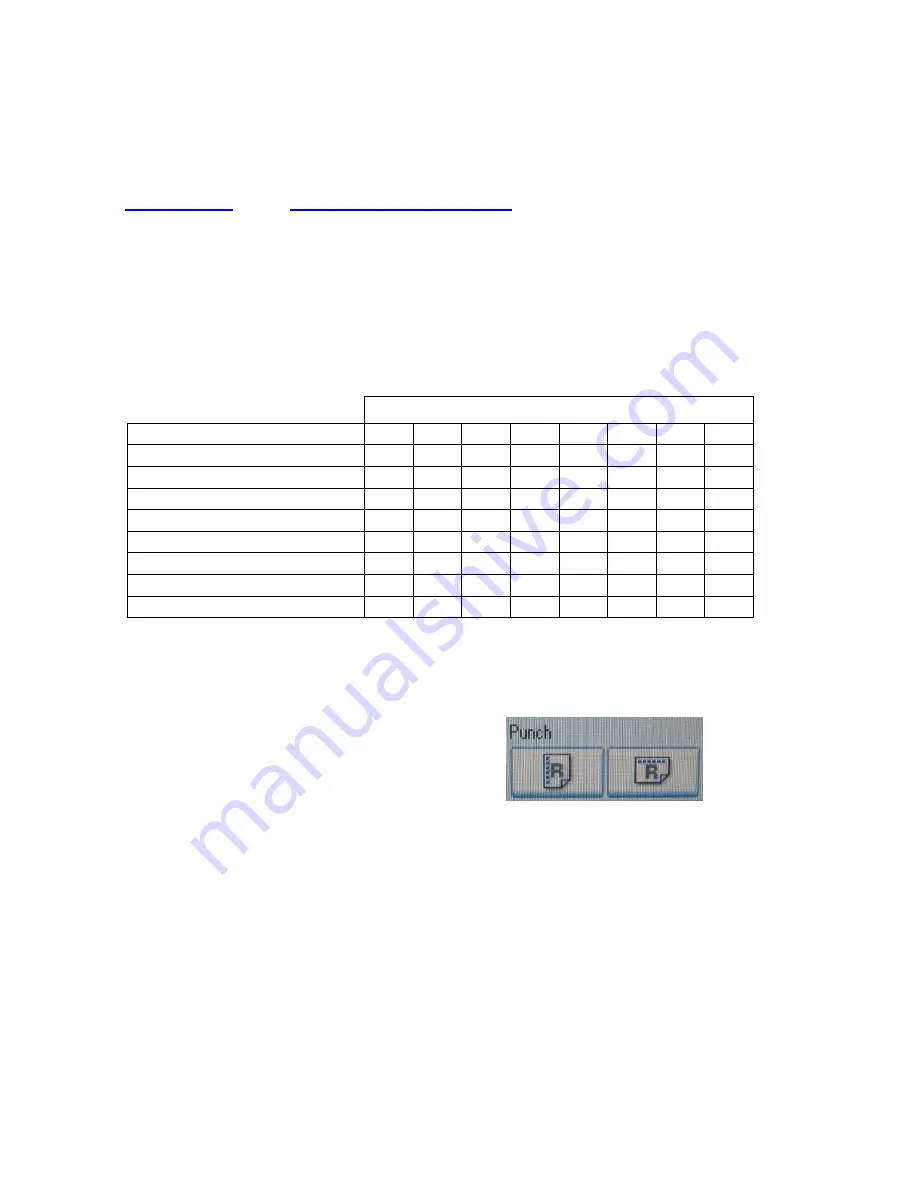

7.2 Setting the Dip Switch

If the unit is fitted with a dip-switch then the setting should be changed depending on the printer it is

attached to. If present, the dip-switch is located next to the firmware upload connector on the rear cover.

If the dip-switch is not present then no setting is required. Set the dip-switch per the table below.

Dip Switch Setting

Printer

1

2

3

4

5

6

7

8

Pro 907/1107/1357EX

OFF

ON

ON

ON

ON

ON

ON

OFF

Pro C900 series

OFF

ON

ON

OFF

OFF

ON

ON OFF

Pro C550/700, MPC6501/7501

OFF

ON

ON

ON

OFF

ON

ON OFF

MP6001/7001/8001/9001 OFF

ON

ON

OFF

ON

ON

ON

OFF

Pro C651/751 EX, Pro C751

OFF

ON

ON

ON

ON

OFF

ON

OFF

MP6002/7502/9002 OFF

ON

ON

OFF

ON

ON

OFF

OFF

MP C8002/ Pro C5100s

OFF

ON

ON

OFF

ON

OFF

ON

OFF

Pro 8100S/8110S/8120S

OFF

ON

ON

OFF

OFF

OFF

ON

OFF

7.3 Enabling the Punch Icon

If the punch icon (shown below) for the Stream Punch option does not appear on the operation panel,

follow the procedure below

:

a) Select User Tools

b) Select Copier/Document Server Features

c) Select Input/Output Tab

d) Select Punch Type-Top Option

e) Select Item-one on the left

f) Select Punch Type-Multiple Hole: Left

g) Exit

Note: If the punch option will not enable due to paper size or direction, change the Original Orientation

(lower left corner of the copier Operation Panel).

7.4 Functional Test

Functional test the StreamPunch system

a) Check to ensure that the paper chip tray is securely in place.

b) Check to ensure that a die set is installed properly and that any extra die sets are securely stored in

the die storage area.

c) Run a small test job in “Bypass” mode. Check to ensure that the job is not punched and bypasses

properly.

d) Run a small job with punch enabled. Check the punched holes of the job.

e) Run each die set to punch 100 sheets or until there is no oil residue around the holes.