4

EN

f) Do not restart the cutting operation in the

workpiece . Let the wheel reach full speed and

carefully re - enter the cut .

The wheel may bind

, walk up or kickback if the power tool is restarted

in the workpiece .

g) Support any oversized workpiece to minimize

the risk of wheel pinching and kickback .

Large

workpieces tend to sag under their own weight .

Supports must be placed under the workpiece near

the line of cut and near the edge of the workpiace

on both sides of the wheel .

UK power plug warnings:

Your product is fitted with an BS 1363-1 approved

electric plug with internal fuse approved to BS 1362.

If the plug is not suitable for your socket, it should

beremoved and an appropriate plug should be

fitted inits place by an authorized customer service

agent.The replacement plug should have the same

fuserating as the original plug.The severed plug

must be disposed of to avoid apossible shock hazard

and should never be inserted into a mains socket

elsewhere.

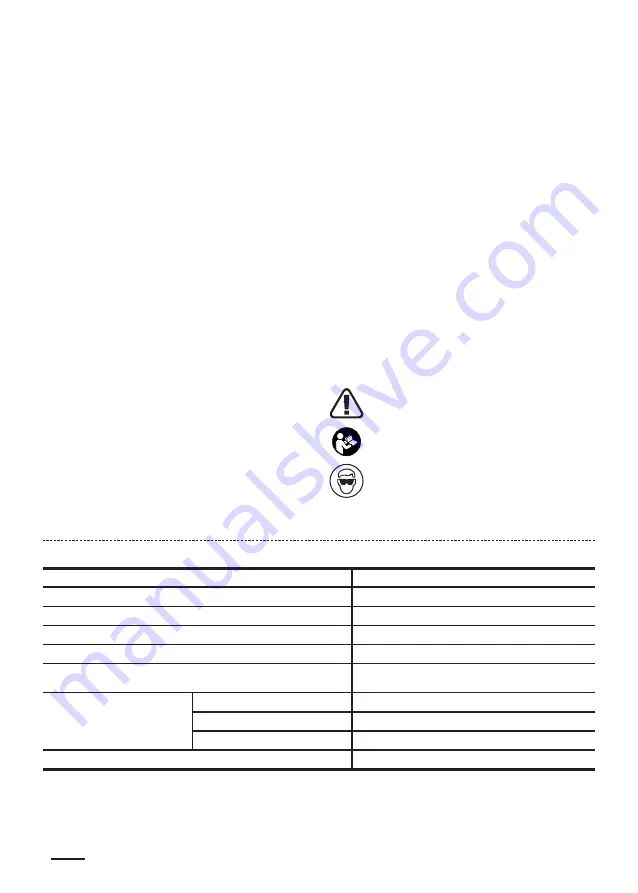

Symbol

To reduce the risk of injury, user must

read instruction manual

WARNING

Always wear eye protection

Technical Data

Model

GM4535

Rated Power Input W

2000

No-load Speed /min

3800

Max. Cutting Angle °

45

Max. Opening Size mm

191

Wheel Size mm

355x3x25.4

Max. Cutting Capacity

Round Bar mm

65

Pipe mm

120

Profiled Bar mm

120x130

Net Weight kg

16

※

Due to the continuing program of research and development, the specifications herein are subject to change

without prior notice.

pinched by the workpiece , the edge of the wheel

that is entering into the pinch point can dig into the

surface of the material causing the wheel to climb out

or kick out . Abrasive wheels may also break under

these conditions .

Kickback is the result of power tool misuse and / or

incorrect operating procedures or conditions and can

be avoided by taking proper precautions as given

below .

a) Maintain a firm grip on the power tool and

position your body and arm to allow you to

resist kickback forces .

The operator can control

upward kickback forces , if proper precautions are

taken .

b)Do not position your body in line with the

rotating wheel .

If kickback occurs , It will propel

the cutting unit upwards toward the operator.

c) Do not attach a saw chain , woodcarving blade

. segmented diamond wheel with a peripheral

gap greater than 10 mm or toothed saw blade .

Such blades create frequent kickback and loss of

control.

d) Do not " jam " the wheel or apply excessive

pressure . Do not attempt to make an excessive

depth of cut .

Overstressing the wheel increases

the loading and susceptibility to twisting or binding

of the wheel in the cut and the possibility of

kickback or wheel breakage .

e) When the wheel is binding or when interrupting

a cut for any reason , switch off the power

tool and hold the cutting unit motionless until

the wheel comes to a complete stop . Never

attempt to remove the wheol from the cut while

the wheel is in motion otherwise kickback may

occur .

Investigate and take corrective acton to

eliminate the cause of wheel binding.