17

MAINTENANCE & TROUBLESHOOTING

GC16XD MINI CRIMPER & PUMP SAFETY & OPERATION MANUAL

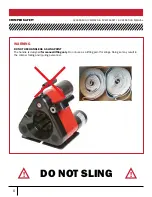

Periodically Redistribute greats build up.

The crimper is designed to automatically redistribute some grease

around the cone. Grease will also build up over time as some is pushed

out. This can be redistributed with a brush periodically. At the rear of

the crimper, use a grease brush to distribute grease inward that has

been pushed out by crimping action. To properly care for your machine

this should be done every 100 crimps, or whenever a

significant amount of grease has been pushed out of circulation.

Warranty is VOID if alternative grease is used.

Periodically check the foam fillers

The foam fillers have been provided to prevent metal partials from

entering the working area.

Always ensure the head is in the OPEN position when storing. If the

shoe Cluster stays together when the head is opened, then to recover,

close and open the head a number of times to re-distribute the grease

and prevent binding.

Warranty is VOID if alternative grease is used.

20 | Gates Corporation

PERIODIC MAINTENANCE

This crimper requires minimal maintenance. However, the following practices are recommended

to ensure maximum reliability and service.

LUBRICATION

Periodically Redistribute grease build up.

The crimper is designed to automatically redistribute some grease

around the cone.

Grease will also build up over time as some is pushed out. This can

be redistributed with a brush periodically.

At the rear of the crimper, use a grease brush to distribute grease

inward that has been pushed out by crimping action. To properly

care for your machine this should be done every 100 crimps, or

whenever a significant amount of grease has been pushed out of

circulation.

Periodically apply fresh Tungsten Disulphide grease.

If cone becomes shiny, use a brush to apply a tablespoon of fresh

Tungsten Disulphide grease around the cone. The machine comes

with Tungsten Disulphide grease, which is far more effective

than alternatives. Do not use alternative grease, as this will

contaminate the grease on your machine.

Using alternatives will

void warranty.

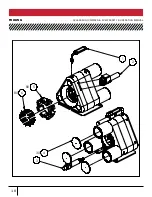

FLANGE HEAD BOLTS

Periodically check torque bolts

.

Check torque on flange bolts every 6 months. Torque settings is

330 Nm, or 243 ftlb.

FOAM FILLER PADS

Periodically inspect filler pads.

The crimper will not retract if foam filler pads are clogged with

grease, in which case the foam filler pads need to be replaced.

Inspect filler pads every 1000 crimp cycles. Foam should return to

original shape after compression. If foam pad does not fill space

between die shoes, order new set and install. (product number)

CHECK OIL LEVEL

Periodically inspect oil level.

Check oil level in pump reservoir after every 10 hours of use.

Hydraulic oil should be visible in sight glass when head is fully

closed.

20 | Gates Corporation

PERIODIC MAINTENANCE

This crimper requires minimal maintenance. However, the following practices are recommended

to ensure maximum reliability and service.

LUBRICATION

Periodically Redistribute grease build up.

The crimper is designed to automatically redistribute some grease

around the cone.

Grease will also build up over time as some is pushed out. This can

be redistributed with a brush periodically.

At the rear of the crimper, use a grease brush to distribute grease

inward that has been pushed out by crimping action. To properly

care for your machine this should be done every 100 crimps, or

whenever a significant amount of grease has been pushed out of

circulation.

Periodically apply fresh Tungsten Disulphide grease.

If cone becomes shiny, use a brush to apply a tablespoon of fresh

Tungsten Disulphide grease around the cone. The machine comes

with Tungsten Disulphide grease, which is far more effective

than alternatives. Do not use alternative grease, as this will

contaminate the grease on your machine.

Using alternatives will

void warranty.

FLANGE HEAD BOLTS

Periodically check torque bolts

.

Check torque on flange bolts every 6 months. Torque settings is

330 Nm, or 243 ftlb.

FOAM FILLER PADS

Periodically inspect filler pads.

The crimper will not retract if foam filler pads are clogged with

grease, in which case the foam filler pads need to be replaced.

Inspect filler pads every 1000 crimp cycles. Foam should return to

original shape after compression. If foam pad does not fill space

between die shoes, order new set and install. (product number)

CHECK OIL LEVEL

Periodically inspect oil level.

Check oil level in pump reservoir after every 10 hours of use.

Hydraulic oil should be visible in sight glass when head is fully

closed.

Summary of Contents for GC16XD

Page 1: ...GC16XD MINI CRIMPER PUMP SAFETY AND OPERATING MANUAL Product Number 7480 7006...

Page 9: ...7 GC16XD MINI CRIMPER PUMP SAFETY OPERATION MANUAL THIS PAGE IS INTENTIONALLY BLANK...

Page 11: ...9 CRIMPER GC16XD MINI CRIMPER PUMP SAFETY OPERATION MANUAL...

Page 22: ...20 NOTES GC16XD MINI CRIMPER PUMP SAFETY OPERATION MANUAL...

Page 24: ...22 7480 7006 70115 GC16XD Auto 428 3509 Ind 34008 M GATES COM Printed in the USA 09 2020...