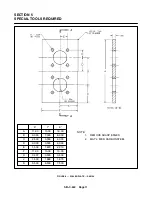

SB--7--622 Page 19

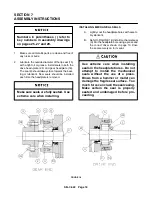

FIGURE 19

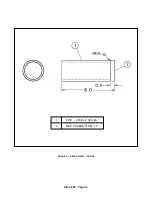

FIGURE 20

3.

Assemble gear headplate (18) and mounting foot

(17) to the impeller case with cap screws (21) and

where the mounting foot is secured to the head-

plate use capscrews (16). The two positioning

dowel pins (19) will ensure proper alignment of the

headplate and impeller case. Also secure lifting

lugs using capscrews (21) (see exploded assem-

bly drawing page 25). Torque capscrews alter-

nately and evenly. Refer to FIGURE 24, page 24,

for torque specifications.

4.

Apply a light oil or grease on the shaft seal areas

and the bearing areas. Insert impellers into the

gear headplate using the same headplate bores

as used in the original assembly.

Seals are delicate; use extreme care

when installing impeller shafts in the

headplate bores. A piece of light shim

stock wrapped around the shaft key-

way will prevent cutting the seal lip.

5.

Position blower so that impellers are vertical, with

the drive end on top. It will be necessary to use

blocks in order for the unit to set level. Measure

the total end clearance using a depth micrometer

(see FIGURE 19).

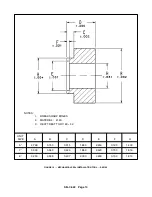

If total clearance is not within the limits specified

in FIGURE 21, page 20, it may be necessary to

shim the case to obtain the proper total end clear-

ance. The shim should be placed between the

drive headplate and impeller case.

If more than .007” shim is required,

put .007” on the drive end and the

remaining on the gear end.

6.

Assemble drive headplate (24) to impeller case as

done in step 3 with the gear headplate. If shims

were required, place shims between drive head-

plate and impeller case.

7.

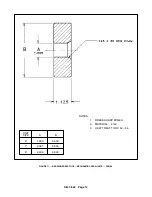

Insert bearing--seal spacers (34), (41) into the

drive shaft headplate bore and spacer (33) into the

remaining bores (see exploded view, page 25).

MECHANICAL SEALS ONLY

A. Refer to FIGURE 18, page18. Lightly coat

the impeller shaft (H) and the inside diameter

of the mating ring (B) with assembly

lubricant.

B. Install the mating ring (B) on the shaft only far

enough to install spacer (34), (41) in the bore

and allow for the bearing inner race (E) to be

started on the shaft.

Summary of Contents for LEGEND GAF P Series

Page 19: ...SB 7 622 Page 12 1 PIPE STEEL 2 SCH 80 2 MED CARBON STEEL 1 2 FIGURE 9 GEAR DRIVER SK2150...

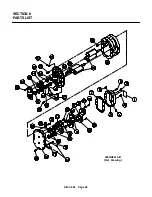

Page 32: ...SB 7 622 Page 25 SECTION 8 PARTS LIST 300GAF810 B Ref Drawing...

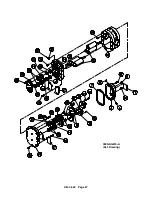

Page 34: ...SB 7 622 Page 27 300GAG810 A Ref Drawing...

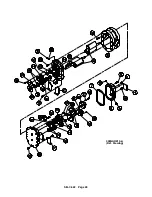

Page 36: ...SB 7 622 Page 29 300GAH810 A Ref Drawing...

Page 39: ......