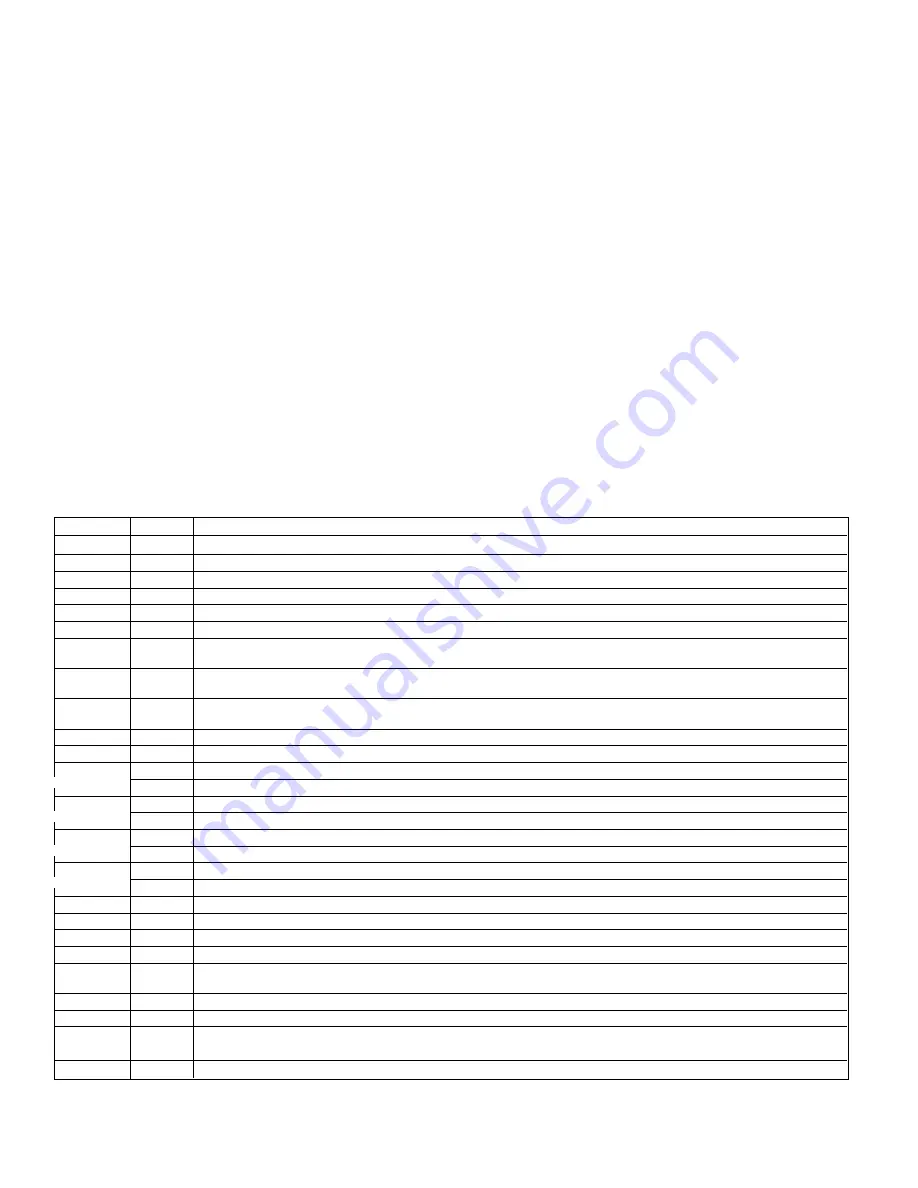

10

I/O Number

Device

Description

I0.0

LPS

Left tower pressure switch (N.O. contacts). The contacts close on rise at 40 psig (2.8 kgf/cm

2

) and open on fall at 10 psig (0.7 kgf/cm

2

)

I0.1

RPS

Right tower pressure switch (N.O. contacts). The contacts close on rise at 40 psig (2.8 kgf/cm

2

) and open on fall at 10 psig (0.7 kgf/cm

2

)

I0.2

BPS

Blower pressure switch (N.O. contacts). The contacts close at approximately 0.5 psig (0.035 kgf/cm

2

)

I0.3

HHC

Heater hi-limit controller output (N.C. contacts). The contacts close if the temperature exceeds 1400

°

F (760

°

C)

I0.4

LTS

Left purge temperature switch (N.O. contacts). The contacts close when the temperature exceeds 150

°

F (66

°

C)

I0.5

RTS

Right purge temperature switch (N.O. contacts). The contacts close when the temperature exceeds 150

°

F (66

°

C)

I0.6

DPM

Dew point montior output (N.O. contacts). The contacts close on rise at 0

°

F (-17.8

°

C) and open on fall at -40

°

F (-40

°

C)

(Optional)

I0.7

Jumper #1

This jumper is present on dryers equipped with the demand cycle option

(Optional)

I1.0

Jumper #2

This jumper is present on dryers equipped with two stage regeneration

(Optional)

I1.1 to I1.5

None

These inputs are not used

AIW0

(Optional)

Analog input module for optional dew point monitor.

Q0.0

1SOL

Left inlet pilot valve (solenoid #1). When the solenoid is energized, pilot air opens the left inlet valve

2LT

Left tower drying light

Q0.1

2SOL

Left inlet pilot valve (solenoid #2). When the solenoid is energized, pilot air closes the left inlet valve

3LT

Left tower regenerating light

Q0.2

3SOL

Right inlet pilot valve (solenoid #1). When the solenoid is energized, pilot air opens the right inlet valve

4LT

Right tower drying light

Q0.3

4SOL

Right inlet pilot valve (solenoid #2). When the solenoid is energized, pilot air closes the right inlet valve

5LT

Right tower regenerating light

Q0.4

5SOL

Left purge pilot valve. When the solenoid is energized, pilot air opens the left purge valve; when de-energized, pilot air closes the left purge valve

Q0.5

6SOL

Right purge pilot valve. When the solenoid is energized, pilot air opens the right purge valve; when de-energized, pilot air closes the right purge valve

Q0.6

7SOL

Left tower depressurization valve. The valve opens when energized and closes when de-energized

Q0.7

8SOL

Right tower depressurization valve. The valve opens when energized and closes when de-energized

Q1.0

9SOL

Repressurization pilot valve. When the solenoid is energized, pilot air opens the repressurization valve; when de-energized, pilot air closes the

repressurization valve

Q1.1

M

Blower motor starter

Q2.0

6LT, CR

Alarm light and remote alarm relay. Both devices are energized during any alarm condition (see Figure 4.10)

Q2.1

10SOL

Air sample switching valve. When the solenoid is energized, air is sampled from the right tower; when de-energized, air is sampled from the left tower

(Optional)

Q2.2 to Q2.7

None

These outputs are not used

Figure 4.6 - Programmable Controller Inputs and Outputs

4.8 Manual Advance

The manual advance feature is used to verify proper

operation of the dryer and to help identify the cause of

an alarm. The use of manual advance is described below.

Read Sections 4.1 through 4.4 before proceeding. Main-

tain the electrical power and compressed air supply to the

dryer while using manual advance.

A. Use the operator interface (see Section 4.4) to select

MANUAL advance (Menu #3). This holds the operating

cycle in its current step.

B. Access Menu #5 using the operator interface (see

Section 4.4) to view the selected cycle (fixed or

demand). Next, go to Menu #6 to view the current

step number. Then refer to Figure 4.7 (fixed cycle) or

Figure 4.8 (demand cycle). These figures show the

on/off status of the programmable controller (PLC)

inputs and outputs during each step of the cycle.

The input and output devices are described in

Figure 4.6. A brief description of each step is given in

Figure 4.9.

NOTE:

If the dryer has one stage regeneration

(standard), the program will skip steps 10 through 13.

C. Compare the LED indicator for each input and output

on the programmable controller with Figure 4.7 or 4.8

for the current step of the operating cycle. Any

differences indicate a potential problem with the

input or output device or the PLC.

D. With Menu #6 displayed, advance the operating cycle

one step by pressing the F2 key on the operator

interface. The step number on the display will update

to show that the cycle has advanced to the next step.

CAUTION:

When advancing the operating cycle

manually, be sure to allow time for depressurization

(steps L02, R02, L11, and R11) and repressurization

(steps L14 and R14) before advancing to the next step.

NOTE:

A false alarm for incomplete heating (Alarm L6

or R6) and/or early dew point breakthrough (Alarm L2

or R2) may occur while using the manual advance

feature.

E. Repeat the procedure in Sections 4.8.C and D until a

complete cycle has been examined.