5

5. Cleaning

(The cleaning agent resistance, the cleaning temperatures and the selection of the

disinfectant should be discussed with the cleaning agent or disinfectant manufac-

turer based on the seal material*)

• Adjust the cleaning intervals based on your cleanliness requirements and your cleaning

plan. We recommend at least daily cleaning, but no later than when dirt is visible.

• If operations are interrupted for a prolonged period, clean at the end of the interruption

and before resumption of operations. We also recommend cleaning at the start of a

long interruption to prevent any adhering substances from drying on the surface.

Procedure for cleaning and, if necessary, disinfection:

1.

Rinse the hand lever with water.

2.

Lather up all surfaces.

3.

A max. temperature of 150 °C for H-NBR and 120 °C for EPDM may not be exceeded

during cleaning.

4.

Rinse off the foam with water (drinking water quality).

A low water pressure (gentle water jet) should be used.

5.

Disinfect, if necessary.

6.

Wash off with water (drinking water quality) at the end of the disinfection.

• All surfaces must be accessible. Ensure that none of the areas are left unsprayed, as

this would result in inadequate cleaning.

• Should manual cleaning be required due to high dirt levels, the following information

should be observed:

· Use additional cleaning tools, such as a soft sponge, cloths or brushes with soft

bristles.

· The cleaning tools must be clean before use.

· Take special care not to damage the seals during manual cleaning.

• Cleaning at high pressures > 7 bar (e.g. with a pressure cleaner) is not recommended.

If a pressure cleaner is nevertheless used, make sure that the pressure can be manually

decreased. The pressure must be set low enough to prevent damage to the seals.

• Do not clean the hand lever or the seals with abrasive means, such as laser beams,

ultrasound or dry ice.

• Impermissible and unsuitable cleaning agents and cleaning utensils that can damage

the hand lever and seals may not be used.

• Never clean the surface with pointed, sharp or scratching tools, such as knives,

brushes or rough cloths.

• After cleaning, the hand lever must be wiped with a lint-free cloth. The area between

the fixed shaft and the moving lever should be cleaned by lifting and lowering the lever

multiple times while wiping.

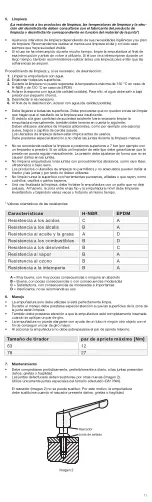

* Guide values for resistances:

A

= Very good, very low or no susceptibility

B

= Good, low to moderate susceptibility

C

= Satisfactory, moderate to severe susceptibility

D

= Insufficient, not recommended for the application

6. Operation

• The hand lever may only be operated in a clean condition.

• During operation, particular attention must be paid to ensuring clean surfaces in the

area around the seal.

• Care must be taken that the hand lever is always fully engaged when introducing a

torque.

• The hand lever may not be extended with a pipe or other objects to achieve a higher

torque.

• When operating the hand lever, never exceed the max. torque.

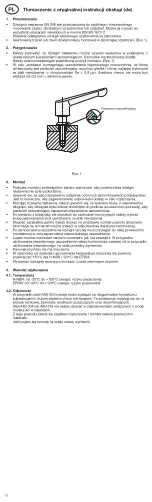

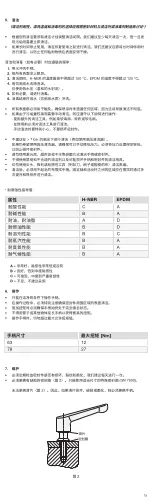

7. Maintenance

• The seals must be inspected for damage, cracks and embrittlement at regular intervals;

we recommend daily.

• Defective sealing rings must be replaced (Fig. 2). Use only the special sealing rings in

the appropriate size (GN 7600).

The wiper (Fig. 2) cannot be replaced. The hand lever must therefore be replaced if the

wiper is damaged, cracked or embrittled.

Fig. 2

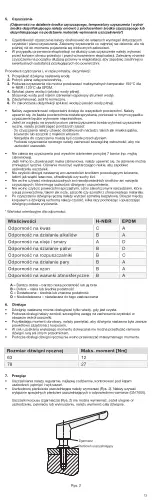

Properties

H-NBR

EPDM

Acid resistance

C

A

Alkali resistance

B

A

Oil and grease resistance

A

D

Fuel resistance

B

D

Solvent resistance

B

C

Steam resistance

B

A

Ozone resistance

B

A

Weather resistance

B

A

Hand lever size

max. torque [Nm]

63

12

78

27