HIWARM

36

All copying, even partial, of this manual is strictly forbidden

RG66007967 - Rev 02

Two pumps are used in HiWarm: one for the utility, for heating or cooling, and one for domestic hot water. The relative pump

is activated according to the request.

The pumps installed are high-effi

ciency type with an inverter driven synchronous motor and fall under energy class A.

Common synchronous motor pumps have a characteristic curve that changes according to the pressure drops that occur.

The operating speed and therefore the fl ow rate are set by the system.

Asynchronous motor pumps have a characteristic curve that is controlled by the unit control microprocessor. The operating

logic can be at constant fl ow rate, constant head or according to the temperature in the heat exchanger.

Nominal useful head of the hydraulic pumps in cooling conditions: water 12/7°C and air 35°C. Inverter driven pumps can run

within the limited range over the characteristic range of the pump.

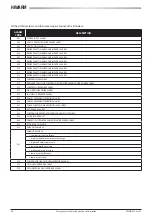

012

Absorbed power

(kW)

0.1

Absorbed current

(A)

0.6

It is extremely important that the installer follows and verifi es the following procedure step by step in order to prevent the

risk of tank implosion or pump cavitation:

- Drain the expansion tank in the system until the pressure reaches 0.5 bar.

- Fill the system and pressurise it to approxi 1 bar in pump suction (pump stopped).

- Bleed the system.

- Check the pump suction pressure (approximately 1 bar) and start-up the system.

- Stop the pump after 15-30 minutes and repeat the procedure from step 3 until no more noise is heard due to air in the

system.

DRAINING THE SYSTEM

Drain outlets must always be set-up in the lower parts of the system. Drain the unit from the connections on the water pipes

beneath the pumps.

5.1.2

Technical data of the hydraulic pumps