Unscrew the two top and bottom retaining

screws

(Fig.5)

and lift the cover from the

backplate. NOTE: Deviations from the

designated entry points will invalidate

product approvals.

required for the Cold water pipe, then a

aperture will need to be cut out of the

cover

(Fig.7)

and the inlet elbow rotated

to face downward.

If entry is required from the back, rotate

the inlet elbow upwards and fit elbow to

connect to the pipe

(Fig.8)

. Ensure the

hole in which the pipe enters through the

wall is filled in completely in order to

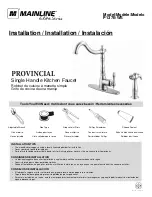

Fig.5

Fig.6

If a top entry is required for the water pipe,

remove the blanking plug in the backplate

(Fig.6)

and ensure the inlet elbow so that

It points upward. If a bottom entry is

Fig.7

Bottom Entry

Aperture

‘Cut-Out’

W

ALL

87 mm

28.5 mm

19 mm

Fig.8

prevent any possible ingress of water into

the cavity area. After choosing the site for

the shower, use the supplied template and

mark the three fixing holes

(Fig.9)

. Drill

and plug to suit the fixing screws supplied.

(The wallplugs provided are suitable for

most brick walls – use an appropriate

masonry drill, but if the wall is

plasterboard or a soft building block, you

must use special wallplugs and an

appropriate drill obtainable from most

hardware stores).

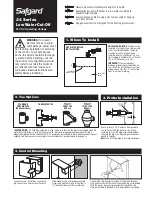

Fig.15

Spindle in

COLD

position

Flat

Fig.12

Fig.14

Element(s) to burn out and invalidate

the guarantee.

The first operation of the shower is

intended to flush out any remaining unit

debris, and to ensure the heater unit

contains water before the elements are

switched on.

This operation must be carried out with

the flexible hose (supplied) screwed to the

outlet but

without

the sprayhead attached.

Ensure the outlet of the flexible hose is

directed to waste and ensure the end of

the hose is below the shower unit.

To ensure the temperature control is

correctly positioned on the stabilising

valve, temporarily place the cover in

position so that the splines engage then

rotate the temperature control knob fully

Anti-clockwise.

Remove the cover and position the

temperature control so that it points

towards ‘TEMPERATURE’

(Fig.13)

.

Position the power selector to the 'COLD'

position

(Fig.12)

.

Ensure power selector is in Cold position

(Fig.14)

before continuing.

Ensure the water supply is still turned on

to the shower.

Open the bleed screw adjacent the rubber

hose

(Fig.15)

by rotating anti-clockwise

slowly until water flows from the drain pipe,

this indicates that any trapped air is

vented and that the pump unit is primed.

The bleed valve must now be closed by

rotating clockwise.

DO NOT

OVERTIGTHEN.

Attach to the stop/start switch inside the

cover is a power lead. The socket on the

end of this lead must be connected to the

plug that is situated near the top of the

backplate unit

(Fig.16)

.

NOTE:

The plug

and socket can only fit one way.

Offer the cover to the backplate unit.

Ensure the power selector is still at the

Bleed Screw

(’XP’ Model)

Fig.13

Fig.12