Screw the two upper fixing screws into

position leaving the base of the screw

heads protruding 6mm (0.25in) out from

the wall. Hook the backplate over the top

screws and fit the lower fixing screw into

position. DO NOT fully tighten the screws

at this stage, as the fixing holes are

elongated to allow for out of square

adjustment after the plumbing connections

have been completed.

10

SECTION

PLUMBING CONNECTIONS

PLUMBING TO PRECEDE WIRING

WARNING:

The outlet of the shower acts

as a vent and must not be connected to

anything other than the hose and

sprayhead supplied.

GALAXY ‘AQUA 9000 XP’

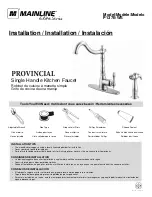

FIXING TEMPLATE

V

E

R

TI

C

AL

C

EN

T

R

E

L

IN

E

HORIZONTAL CENTRE LINE

Fig.9

DO NOT

use jointing compounds on

any pipe fittings for the installation.

DO NOT

use soldered fittings within

the vicinity of the shower unit.

NOTE:

An additional gate valve or fullway

lever valve must be fitted in the water

supply to the shower as an independent

means of isolating the water supply should

maintenance or servicing be necessary.

IMPORTANT:

The fitting on the inlet elbow

is a push-in type. The pipework must be

cut with a pipe cutter and all burrs and

rough edges removed from the end of the

tube. The fitting can be used with copper

and plastic pipe. If using chrome plated

copper pipe, remove the first 25mm of

plating completely from the connecting

surface. If it is not completely removed

then the collet will not grip the pipe and

under pressure the pipe may be forced

out.

CONNECTION PROCEDURE: Turn off

water supply either at the mains stopvalve

or the isolating stopvalve to the cistern.

Drain the cistern.

IMPORTANT:

T

he pipework must be

brought direct from the Cold water storage

cistern with no other Cold water draw offs

between the shower and the cistern.

IMPORTANT: Before completing the

connection of the water supply to the

inlet of the shower, flush out the

pipework to remove all swarf and

system debris. This can be achieved by

connecting a hose to the pipework and

turning on the water supply long

enough to clear the debris to waste.

Fit the pipework to the inlet elbow. Ensure

the elbow collet is fully engaged with the

pipe. Although the pipework connection to

the shower is via 15mm diameter

pipework, on long runs use 22mm

diameter piping as far as possible to avoid

restricting the flow to the shower.

Ensure that the backplate of the unit is flat

on the wall and positioned squarely.

Tighten the fixing screws.

Turn on the water supply and check for

leaks in the pipework connection to the

shower.

NOTE:

At this stage no water can

flow through the unit.

11

SECTION

ELECTRICAL

CONNECTIONS

SWITCH OFF THE ELECTRICITY

SUPPLY

The cable entry points are shown in

(Fig. 10).

The cable can be surface clipped, hidden

Or via 20mm conduit. NOTE: Metal

conduit entry can only be from rear.

Route the cable into the shower unit and

connect to the terminal block

(Fig. 11)

As

Follows:-

Earth cable to terminal marked ......

Neutral cable to terminal marked ...

N

Live cable to terminal marked.........

L

E

IMPORTANT: Fully tighten the terminal

block screws and ensure that no cable

insulation is trapped under the screws.

Loose connections can result in cable

Overheating.

.

Fig.11

NOTE: The supply cable earth conductor

must be sleeved. The outer sheath of the

supply cable must be stripped back to the

minimum. The supply cable must be

secured either by routing through conduit

or in trunking or by embedding in the wall,

in accordance with current IEE regulations.

The use of connections within the unit, or

other points in the shower circuit, to

supply power to other equipment i.e.

extractor fans, pumps etc. will invalidate

the guarantee.

DO NOT switch on the electricity

supply until the cover has been fitted.

Fig.10

12

SECTION

COMMISSIONING

DO NOT switch on the electricity

supply until the following procedure

has been completed and the cover has

been fitted. Failure to do so could

Cause the pump to run dry and

invalidate the guarantee.

Cold position must be selected on

power selector (Fig.14) Before carrying

out any of the steps below. Failure to

do so

WILL

cause the heating