SMART PRO 5.0 Pág. 32

4.3.2 Manipulation of electrode

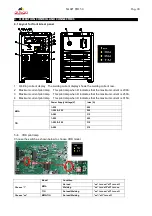

In MMA welding, there are three motions to being matched in the

end of electrode: the electrode moving to the molten pool along

axes; the electrode swing right and left; the electrode moving

along welding way.

The operator can choose the manipulation of electrode based on

welding joint shape, welding position, electrode spec, welding

current and operation skill, etc.

The details please refer to

《

Welding Dictionary

》

P69, Volume 1

of Edition 2.

4.4 Welding parameters

Joint form in MMA

In MMA welding, the common basic joint form: butt joint, lap joint, corner joint & T joint.

Electrode selection

The electrode diameter selection is based on the workpiece thickness, welding position, joint form, welding

layer, etc. Please refer to the following table.

The welding current reference for different electrode diameter

Electrode

diameter/mm

1.6

2.0

2.5

3.2

Welding

current/A

25

~

40

40

~

60

50

~

80

100

~

130

The relation between the welding current(I)’ factor(K) & electrode diameter(d) (I

=

K×d: Carbon

electrode)

Electrode

diameter/mm

1.6

2

~

2.5

3.2

Factor/K

20

~

25

25

~

30

30

~

40

Notice: the above parameters originate from

《

Welding Dictionary

》

P66

~

P67, Volume 1 of Edition 2.

Electrode should be drying according to user manual before using. For reducing the hydrogen of the

molten pool and welding seam, and avoiding the blowhole and cold crack.

In the welding process, the arc must not be too long; otherwise, it will cause unstable arc burning, large

spatter, light penetration, undercut, blowhole, etc. If the arc is too short, it will cause electrode stick.

In MMA welding the arc length is usually equal to 0.5~1.0 time of the electrode diameter. The basic

electrode’s arc length is not beyond the electrode diameter, it’s better to choose the short arc welding;

the acid electrode’s arc length is equal to the electrode diameter.

butt joint

lap joint

corner joint

T joint

electrode

workpiece

weld

1

2

3

2

1-electrode moving; 2-the electrode swing right & left; 3-the electrode move along weld