SMART PRO 5.0 Pág. 22

1. SAFETY

1.1

1.1

1.1

1.1 Signal Explanation

Signal Explanation

Signal Explanation

Signal Explanation

The above signals mean warning! Notice! Running parts and getting an electric shock or thermal parts will

take damage for your body or others. The corresponding notices are as follows. It is quite a safe operation

after taking several necessary protection measures.

§1.2

§1.2

§1.2

§1.2 Arc Welding Damage

Arc Welding Damage

Arc Welding Damage

Arc Welding Damage

The following signals and word explanations are to some damages for your body or others happening on

the welding operation. While seeing these, please remind of yourself or others to be dangerous.

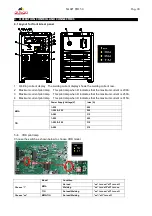

Only ones who are trained professionally can install, debug, operate, maintain and repair the equipment.

During the operation, non-concerned people should be lift, especially for children.

After shut off the machine power, please maintain and examine the equipment according to §5 because

of the DC voltage existing in the electrolytic capacitors.

ELECTRIC SHOCK CAN KILL.

ELECTRIC SHOCK CAN KILL.

ELECTRIC SHOCK CAN KILL.

ELECTRIC SHOCK CAN KILL.

Never touch electrical parts.

Wear dry, hole-free gloves and clothes to insulate yourself.

Insulate yourself from work and ground using dry insulation. Make certain the insulation is large enough

to cover your full area of physical contact with work and ground.

Take carefully when using the equipment in small place, falling-off and wet circumstance.

Never close the machine power before installation and adjustment.

Ensure to install the equipment correctly and ground the work or metal to be welded to a good electrical

(earth) ground according to the operation manual.

The electrode and work (or ground) circuits are electrically “hot” when the welder is on. Do not touch these

“hot” parts with your bare skin or wet clothing. Wear dry, hole-free gloves to insulate hands.

In semiautomatic or automatic wire welding, the electrode, electrode reel, welding head, nozzle or

semiautomatic welding gun are also electrically “hot”.

Always be sure the work cable makes a good electrical connection with the metal being welded The

connection should be as close as possible to the area being welded.

Maintain the electrode holder, work clamp, welding cable and welding machine in good, safe operating

condition. Replace damaged insulation.

Never dip the electrode in water for cooling.

Never simultaneously touch electrically “hot” parts of electrode holders connected to two welders because

voltage between the two can be the total of the open circuit voltage of both welders.

When working above floor level, use a safety belt to protect yourself from a fall should you get a shock.