SMART PRO 5.0 Pág. 31

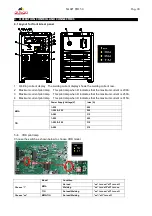

7 Power pilot lamp This pilot lamp when lit indicates that the machine is on.

8 Alarm pilot lamp When the machine less voltage, over current, or over heat, This pilot lamp indicates

when lit that the protection of the machine has been activated.

9~12 Rod electrode welding key

Parameter Setting range

Arc force 0-10

Hot start 1-10

Arc length 1-10

13 Conversion switch Choose TIG.

14 Connector

The welder’s positive polarity output.

15 Welding current regulation Set welding current.

16 Connector The welder’s negative polarity output.

17 Power source input

To connect power source.

18 Power switch Choose “ON”, power through; Choose “OFF”, power cut off.

4.2 Welding current adjustment

GM series welder has the function of welding current pre-setting. Before welding,

adjusting welding current, the welding current display will show the ampere. It is

convenient to set parameters and adjust accurately.

4.3 Welding operation

4.3.1 Striking arc way

Knocking arc: take the electrode upright to touch the workpiece, after forming short circuit, quickly lift up

about 2~4 mm, and arc will be ignited. This method is difficult to master. But in the welding for the brittle

or hard steel, it is better to use knocking way.

electrode

workpiece

electrode

electrode

workpiece

workpiece

Take the electrode upright

The Electrode touch the workpiece

Lift up for about 2-4mm

upright

up

touch

2

~

4mm

Lifting arc: take the electrode to scrape the workpiece for striking arc. But it may cause the arc

scratch, so must to lift arc in the groove.