6

Governors America Corp. © 2021 Copyright All Rights Reserved

ESD5500-II Fusion Series Speed Control Unit 1-2020-A4 PIB2180

12

ADDITIONAL FEATURES & OPTIONAL WIRING

Droop

Idle

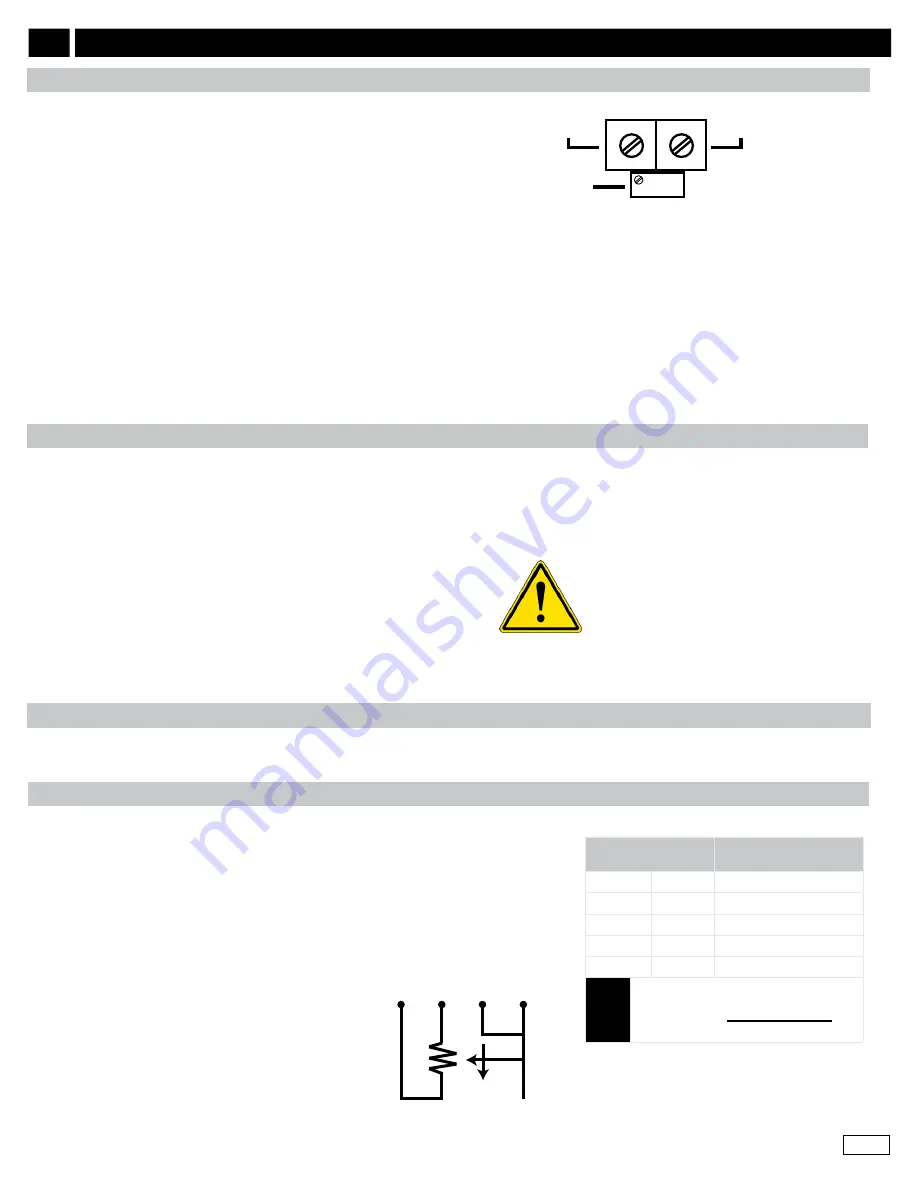

Speed

SPeeD ranGe

PoTenTIomeTer

vaLUe

900 Hz

540 RPM

1 K

2400 Hz

1440 RPM

5 K

3000 Hz

1800 RPM

10 K

3500 Hz

2100 RPM

25 K

3700 Hz

2220 RPM

50 K

noTe

RPM values shown are for 100 teeth flywheel

MPU Signal (Hz) = RPM x Flywheel Teeth

TaBLe 1

60 s

G

J

K

L

CW

*

* Select proper potentiometer

value from Table 1

POTENTIOMETER WIRING

Droop is based on a speed sensor frequency of 4000 Hz. and an actuator current change of 1 amp from no load to full load. Applications with

higher speed sensor signals will experience less percentage of droop. Applications with more actuator currant change will experience higher

percentages of droop.

Though a wide range of droop is available with internal control, droop level requirements of 10% are unusual. If droop levels experienced are

higher or lower than those required, contact GAC for assistance.

1. Terminal N is sensitive. Accessory connections must be shielded.

2. When an accessory is connected to Terminal N, speed will de-

crease and speed adjustment must be reset.

3. When operating in the upper end of the control unit frequency

range, a jumper wire or frequency trim control may be required

between Terminals G and J. This increases the frequency range of

the speed control to over 7000 Hz (4200 RPM).

4. If the auto synchronizer is used alone, not in conjunction with a load

sharing module, a 3 ohm resistor should be connected between Termi-

nals N and P. This is required to match the voltage levels between the

speed control unit and the synchronizer.

A short circuit on Terminal N can damage the

speed control unit.

Never jumper Terminal P directly to Terminal N.

Droop is typically used for paralleling engine-driven generators. When in droop

operation, the engine speed will decrease as engine load increases. The per-

centage of droop is based on the actuator current change from no engine load

to full load. Factory setting for Droop is 0%.

To set droop:

1. Place the optional external selector switch in the Droop position. Droop is

increased by clockwise rotation of the Droop adjustment control.

2. After the droop level has been adjusted, the rated engine speed setting may

need to be reset. Check the engines speed and adjust that speed setting

accordingly.

The AUX Terminal N accepts input signals from load sharing units, auto synchronizers, and other governor system accessories, GAC acces-

sories are directly connected to this terminal.

The following apply when using the accessory input:

The +10 volt regulated supply, Terminal P, can be utilized to provide power to GAC governor system accessories. Up to 20 mA of current

can be drawn from this supply. Ground reference is Terminal G.

SPeeD DrooP oPeraTIon

acceSSorY InPUT

acceSSorY SUPPLY

A single remote speed adjustment potentiometer can be used to adjust

the engine speed continuously over a specific speed range. Select the

desired speed range and corresponding potentiometer value. (TABLE 1)

If the exact range cannot be found, select the next higher range potenti-

ometer.

Place an additional fixed resistor across the potentiometer to obtain the

exact desired range. Connect the speed range potentiometer using

Terminals G and J.

To maintain engine stability at the minimum speed set-

ting, a small amount of droop can be added using the

DROOP adjustment. At the maximum speed setting

the governor performance will be near isochronous,

regardless of the droop adjustment setting.

WIDe ranGe remoTe varIaBLe SPeeD oPeraTIon